Precision is a critical factor in edge banding, and the HUAHUA CNC HH-406RP excels in this area thanks to its cutting-edge technology. The high-precision control of the servo motor guarantees accurate positioning of the panel during our edge banding process, significantly enhancing the quality of our finished products.

Preheating Capability for Superior Adhesion

One of the key features of the HH-406RP is its ability to preheat panel edges. This capability is essential for preventing cracking due to significant temperature differences. By ensuring that the panel is adequately warmed before the edge banding process begins, we can achieve not only a smoother application but also superior adhesion of the edge material. This attention to detail ensures that our finished products meet the highest quality standards.

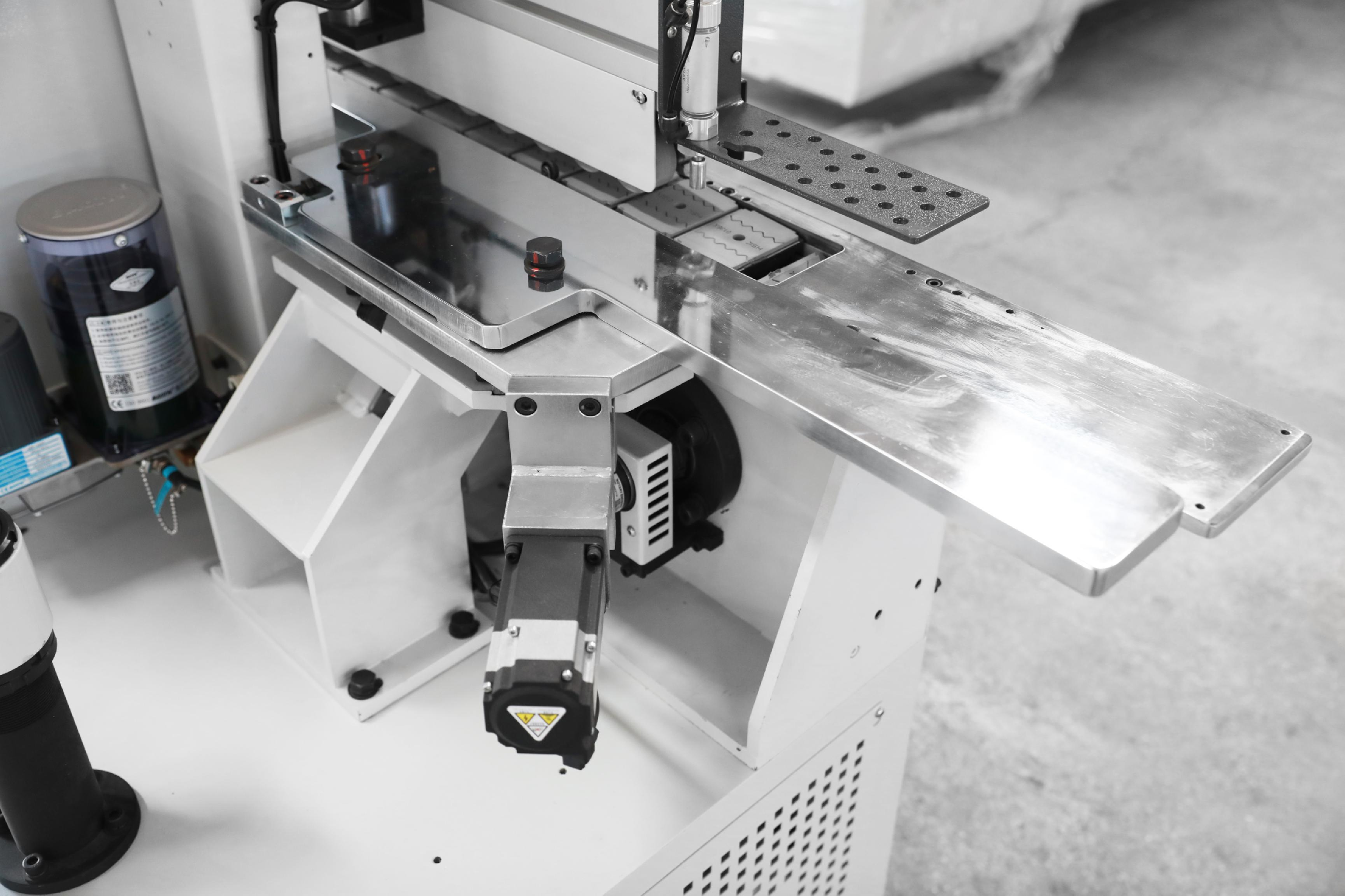

Strong Pressing Mechanism for Consistency

The machine’s design includes four strong pressing wheels and one rubber wheel, ensuring a tighter fit during the edge banding process. The enlarged diameter of the pressing wheel, measuring 150mm, improves coverage and enhances efficiency. This attention to detail guarantees that every panel receives uniform treatment, resulting in a consistently high-quality finish that we can be proud of.

Advanced Feedback System for Real-Time Adjustments

Moreover, the HUAHUA CNC HH-406RP features an advanced feedback system that monitors the positioning of the panel throughout the edge banding operation. This system allows for real-time adjustments, ensuring that we maintain accuracy even during high-speed operations. As a result, we can complete projects more quickly while still upholding the highest standards of quality, thereby increasing our overall productivity.

Robust Construction for Longevity

The servo edge banding machine’s robust construction minimizes vibrations, which can adversely affect precision. The HH-406RP operates smoothly, providing us with the confidence that our edge banding will be flawless every time. This quality construction reflects our dedication to producing machines that stand the test of time, making the HH-406RP a reliable choice for our woodworking needs.

Superior Dual-Disc Monitoring System

Both big and small discs are used in the dual-disc automated tracking mechanism of the HUAHUA CNC HH-406RP. High-frequency and high-speed motor performance is made possible by this creative design, which guarantees that our edge banding procedure stays constant. These characteristics work together to enable the machine to mill the tapes that are adhered to the panel’s top and bottom sides into a smooth R-shaped edge. Our reputation for excellence is strengthened by this attention to detail, which produces a product that not only looks fantastic but also endures over time.

Conclusion

By investing in the HUAHUA CNC HH-406RP, we ensure that our edge banding is not only precise but also of the highest quality. This servo edge banding machine focuses on precision and detail, allowing us to achieve the best results, making it an essential tool in our woodworking operations.