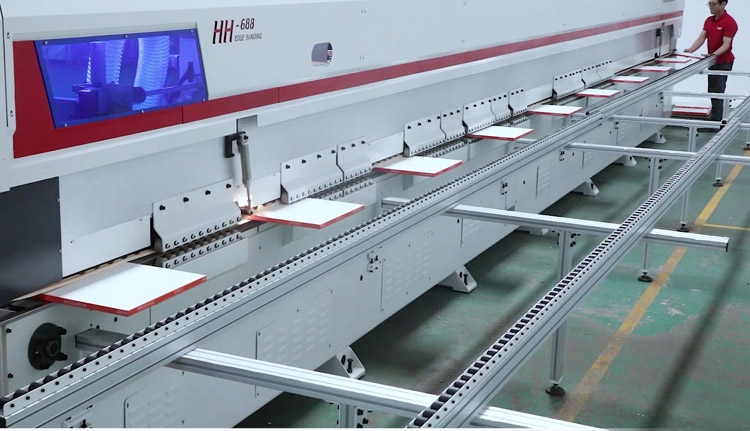

Automatic Edge Banding Machine

- Home

- Automatic Edge Banding Machine

Filter By:

High Speed Edge Banding Machine

With 19 years of manufacturing experience and strong R&D, we are confident to bring you advanced edge banding machines and market-oriented edge banding solutions that boost the capacity of your panel processing lines.

- Affordable Price

- Ease of Operation

- Detail-Driven Edge Banding Process

- Full Range of Optional Equipment

Every Detailed Optimization Perfects Edge Banding Process

Well Pre-mill, Half Done

The pre-milling unit grinds edges of panels at the beginning, which helps to firmly stick the banding tape to the panel in the later process.

Water-Proof PUR Glue

The PUR(poly urethane resin) glue used in the gluing device features water-proof and damp-proof. This better prevents wood panels from potential damage.

Auto-track Trimming

Double trimming discs automatically track panels to remove the excessive glue and tape, achieving more soomth appearance of panels, which certainly pleases the end-market.

Corner Rounding & Polishing

In order to help you produce perfect panel furnitures, HUAHUA persues flawless edge banding procedures. The corner rounding device and cloth polishing wheels perfect your panel processing line.

Automatic Edge Banding Machine ABC

Know more about HUAHUA’s Automatic Edge Banding Machines.

So let’s start from scratch. What is edge banding? It’s pretty simple, and the edge banding video will help you understand it better, but here’s a quick overview to get you started.

This is a basic non-technical concept. Plywood, particleboard, and other artificial wood cores such as MDF have rough, untreated, unprotected, and often unsightly edges.

To accommodate this, some intelligent people have developed a technique that allows you to glue strips of different shiny materials to rough edges to match the top and sides.

These narrow tapes or strips are called edge bands, range in thickness from 0.018″ to 5mm thick, and are supplied in 250ft reels.

Thicker edges are used in high-traffic and commercial environments to provide greater resilience and impact resistance. For example, the military requires wider ⅜ inch solid wood edge tape for maximum impact resistance. Edgebanders are industrial-grade machines that use hot melt adhesive or glue to apply edgebanding to the cut edges of boards.

Edge banding serves both functional and aesthetic purposes.

Functionally, edge bands perform some essential duties for your furniture. First, they keep moisture out, serving as de facto seals on the edge of the core material. Second, edge banding improves durability and resilience by providing impact resistance. If you’re using solid wood edging, it can also add to the overall strength of the furniture.

Aesthetically, edge banding covers up unsightly rough edges and creates a glossy finish to match your tops and sides. You can also develop radial edges to soften sharp angles.

Where can you expect to find edge banding in your furniture? That depends on your overall material specification.

A solid wood product won’t include any edge banding except where we can’t use solid wood. Wardrobe doors, for example, are made of veneer core plywood or MDF.

And even when we use solid wood for case sides and drawer fronts, many customers still use high-pressure laminate tops. Those tops need edge banding.

If you’re using plywood or laminate as your material specification, that needs edge banding too.

We suggest doesn’t use edge banding on cabinet backs or drawer bottoms because they are already embedded (sealed) in dato grooves. Likewise, we don’t edge band internal plywood drawer parts because it doesn’t add value.

You should note that some manufacturers don’t use edge banding where they should—like on the bottom and back edges of plywood cabinets. That’s a problem because moisture, even small amounts, can destroy unsealed furniture.