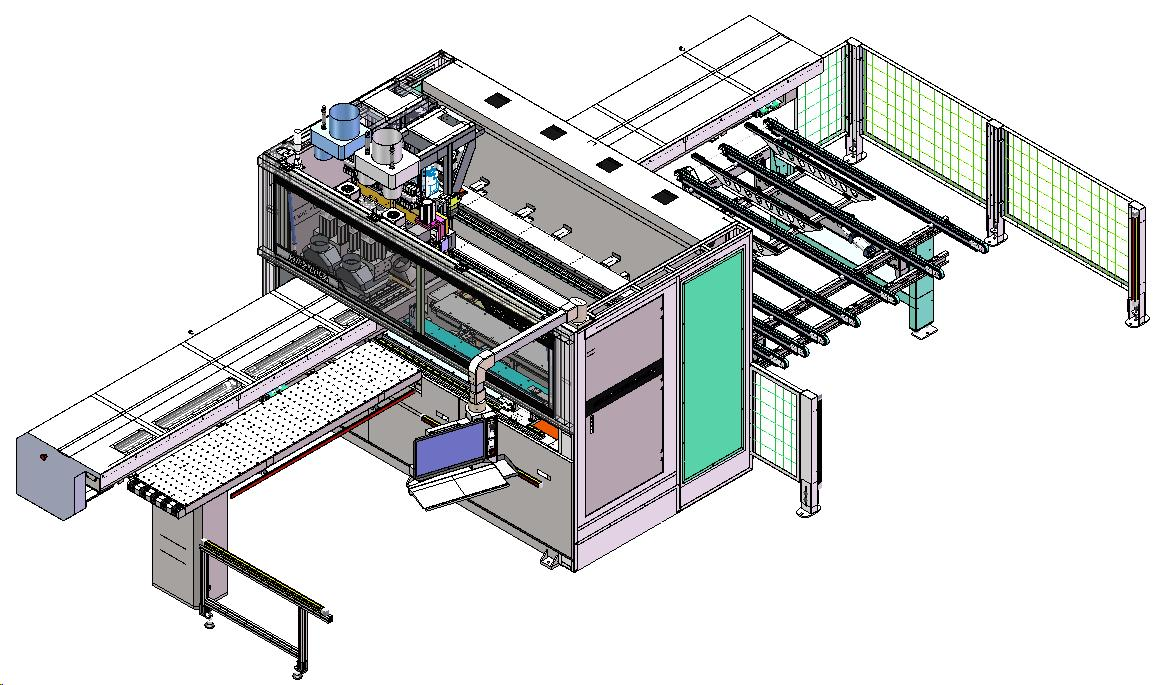

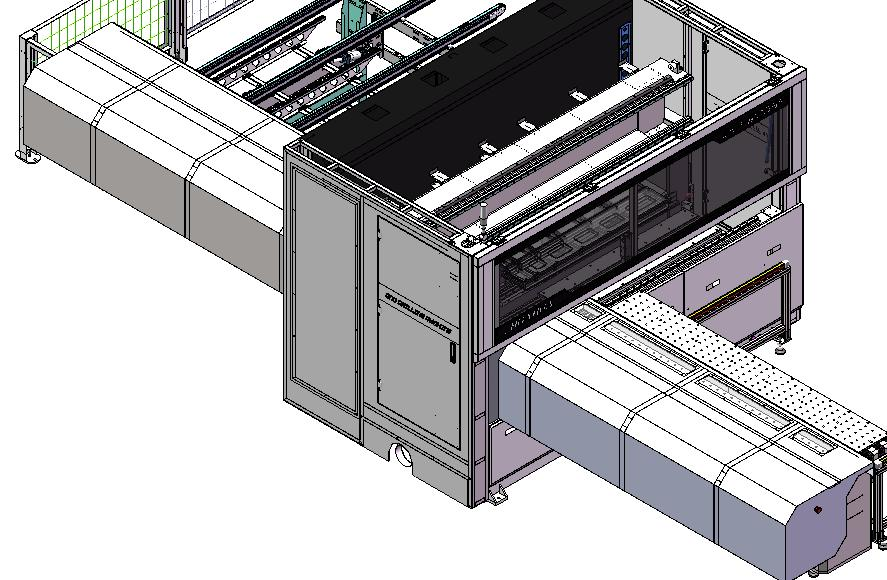

SKH-612GMSF

SKH-612GMSF

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

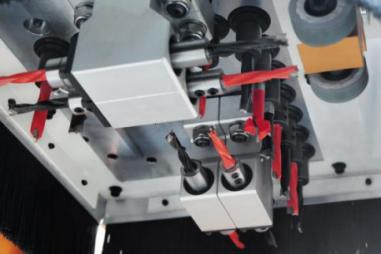

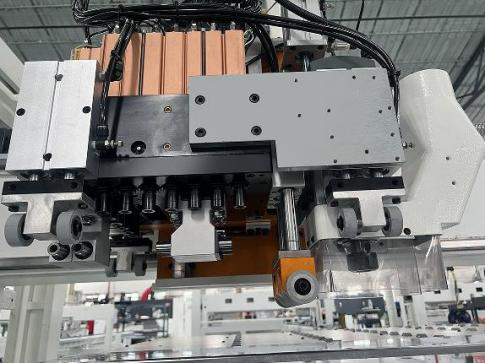

Drilling Head

Adopt high-precision CNC drilling head independently developed by HUAHUA.

Adopt Huahua brand motor, perfect match.

Two top drilling heads and one bottom drilling heads.

Drilling Bits

Top drilling head: 16pcs vertical drilling bits *2sets,8pcs horizontal drilling bits *2sets.

Bottom drilling head: 9pcs vertical drilling bits.

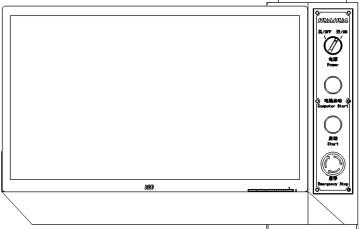

Screen Control Display

Simple human-computer interaction.

Adopt 21-inch color screen control display.

Single-arm suspension, easy to operate, saving space.

Safe and reliable operation, simple and friendly

interface.

Comes with complete operating tips and troubleshooting guidelines.

21-inch color screen control display

Adopt 21-inch color screen control display,

Single-arm suspension is easy to operate and saves space.

Safe and reliable operation, simple and friendly interface,

Comes with complete operating tips and troubleshooting guidelines

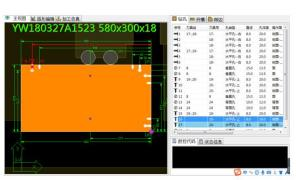

Control System

Taiwan Syntec control system.

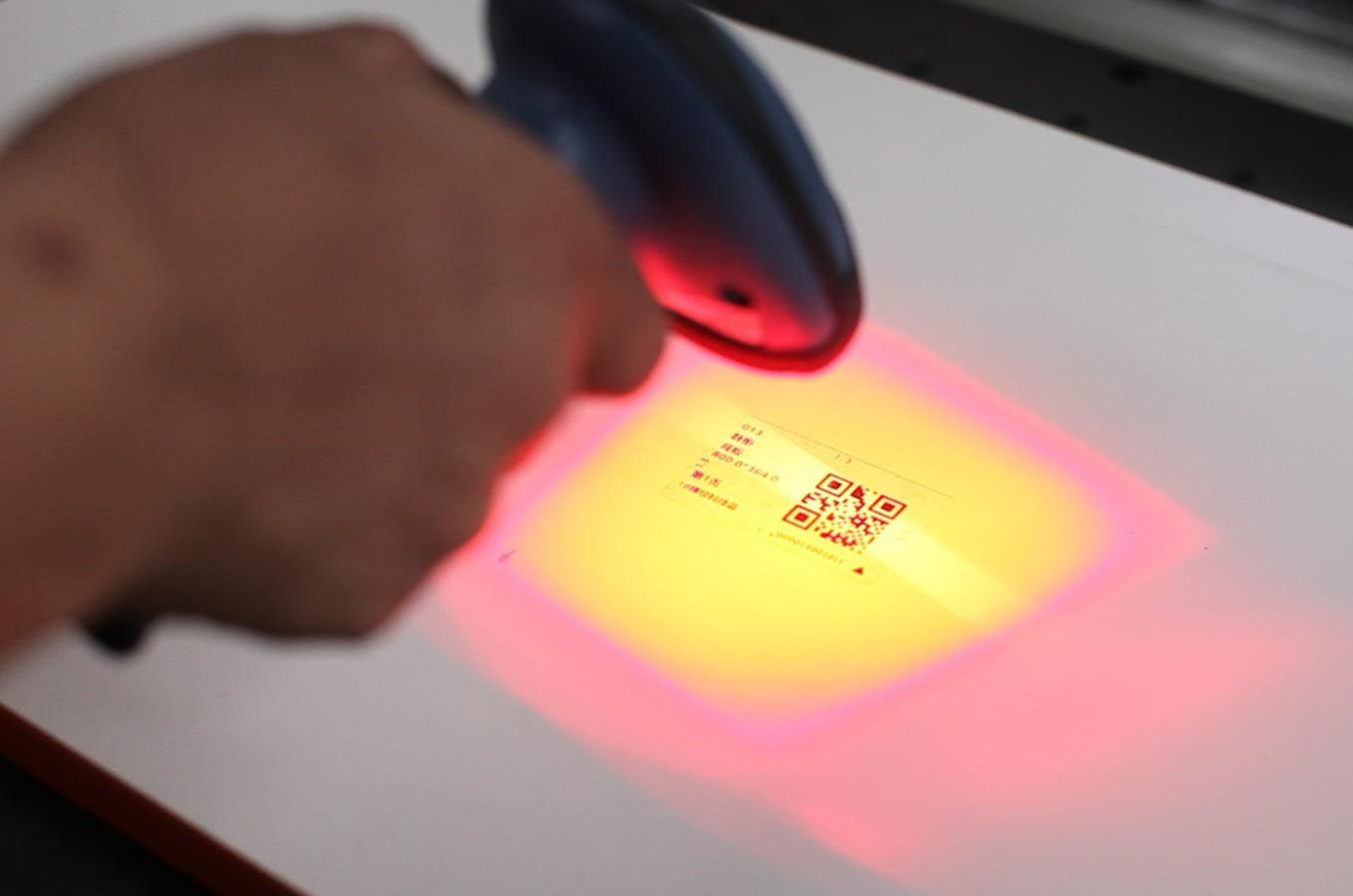

Drilling data can be loaded by using CAD, quick and convenient to operate.

Match with user production design management software, no need to input drilling data independently.

QR code scanning, automatically load processing graphics files and generate processing programs.

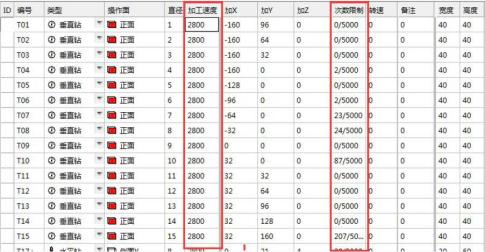

Database Support

Continuous scanning: Bar-code/QR code is acceptable,scans to automatically load processing graphics files and automatically retrieve NC programs for processing.

Database Support

Data analysis system: Automatically analyzes the panel data after scanning, and visually displays the size, depth and coordinate information of the panel holes to facilitate data query and correction.

Database Support

Independently adjust tool processing speed: Through processing data analysis, the processing speed is customized for each drill bit, making production and processing more flexible.

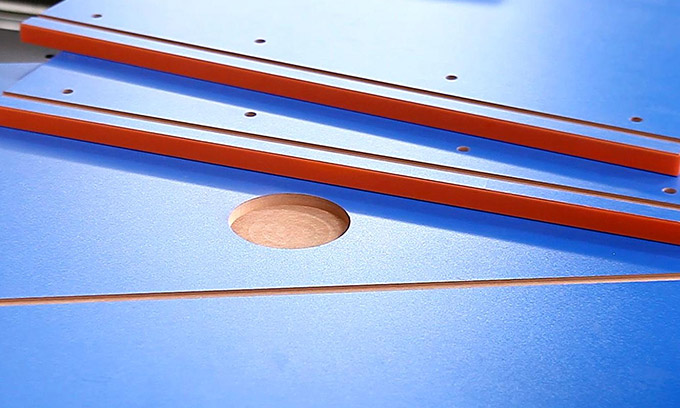

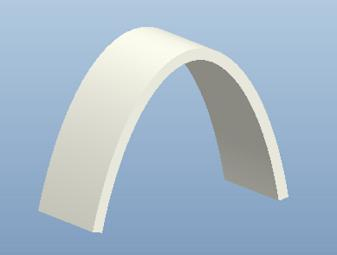

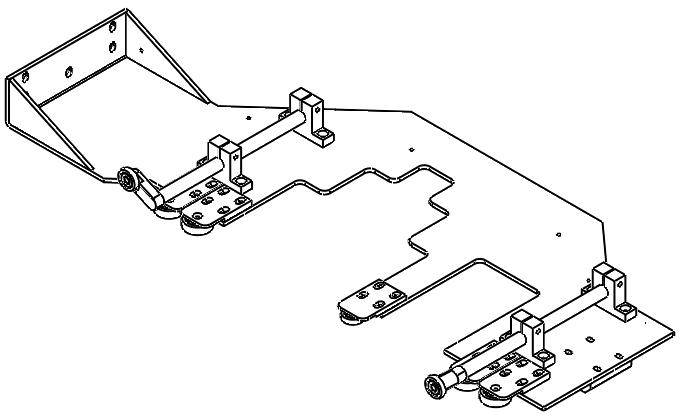

Double Clamps

The first C-shaped groove double clamps to ensure drilling accuracy.

Automatically control the panel feeding and positioning according to the computer drilling program, greatly improving the drilling accuracy.

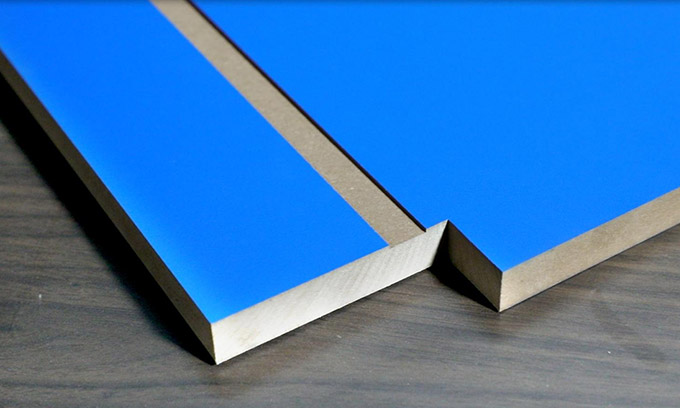

Effectively prevent edge banding from being .scratched

Four clamps is optional.

Automatic Pressing Device

Ensure drilling hole precision.

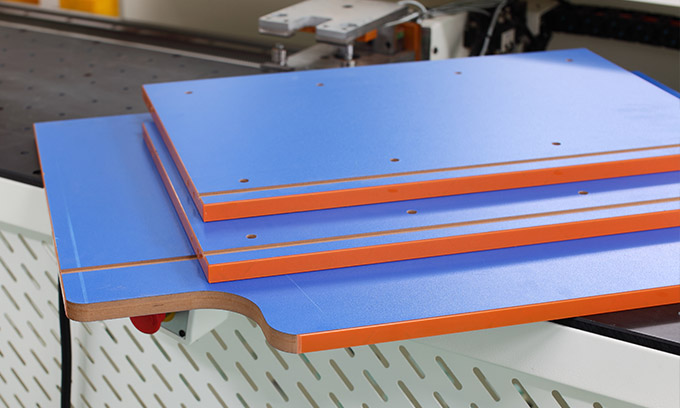

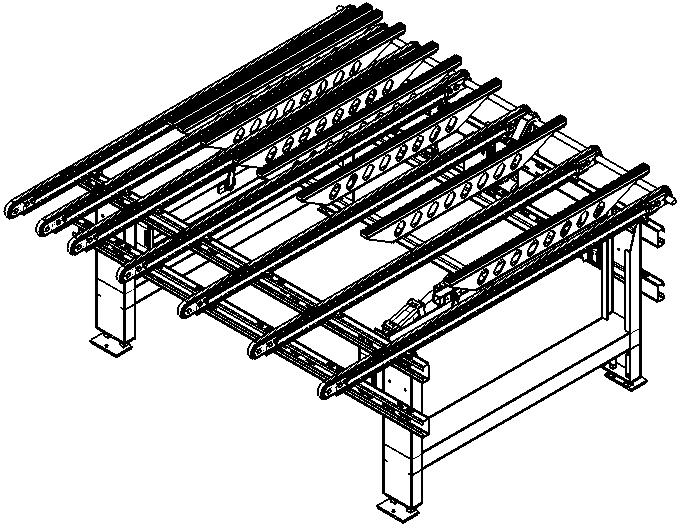

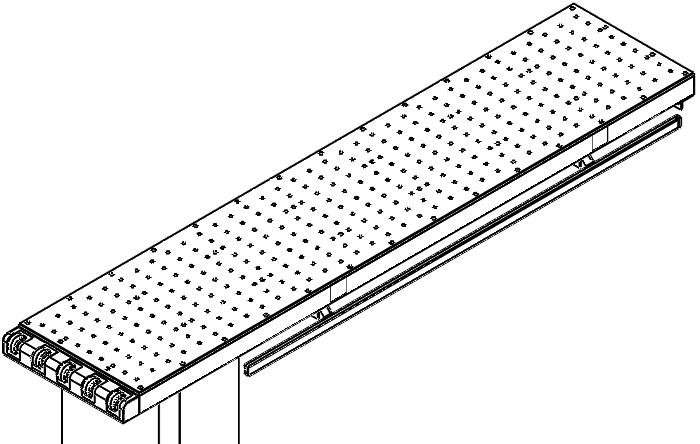

Side Discharge Platform

The panel is transported horizontally

Adopt the 19mm width translation synchronous belt, 3mm thickness APL rubber, made of high-temperature and wear-resistant material.

The minimum panel that can be transported is 150*150mm and the maximum panel is 1220*2440mm.

Frog-leaping Technology

First frog leaping technology

Parabolic trajectory reduces empty operating time, fast drilling speed, improving efficiency.

Side Aligner

E-type side align plate automatically closes to the panel.

Prevent the panel from jumping or running, thus reducing processing errors.

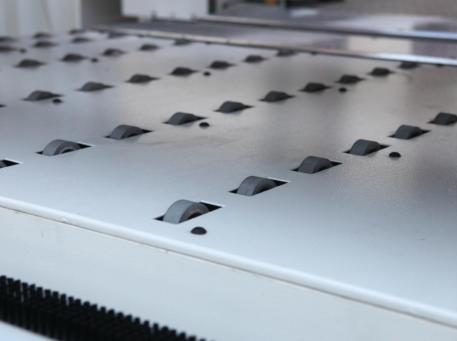

Air floating working table

Prevent the panels from scratching.

Roller Assisted convey table

Prevent the panels from scratching.

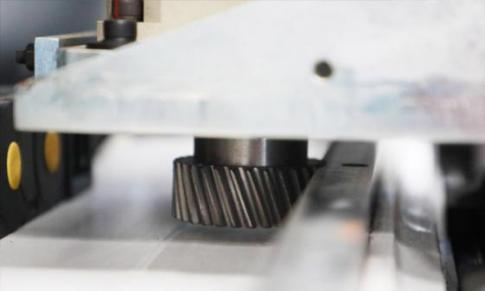

Rack & Pinion Transmission

Rack and pinion constant transmission

The rack and pinion is used to transmit the motion power between any two axis and can ensure constant transmission.

Guide Rail

German ROUST guide rail.

Dust-proof design allows smooth travel.

Extended running guide rail, no limit to the length of processed panels.

One-time positioning reduces the number of clamp changes for the clamp hand, increasing plate processing speed.

Servo Motor

Taiwan Syntec, high-precision position.

Servo motor to control clamps, quick and precise position.

Speed of clamps can reach to 130m/min.

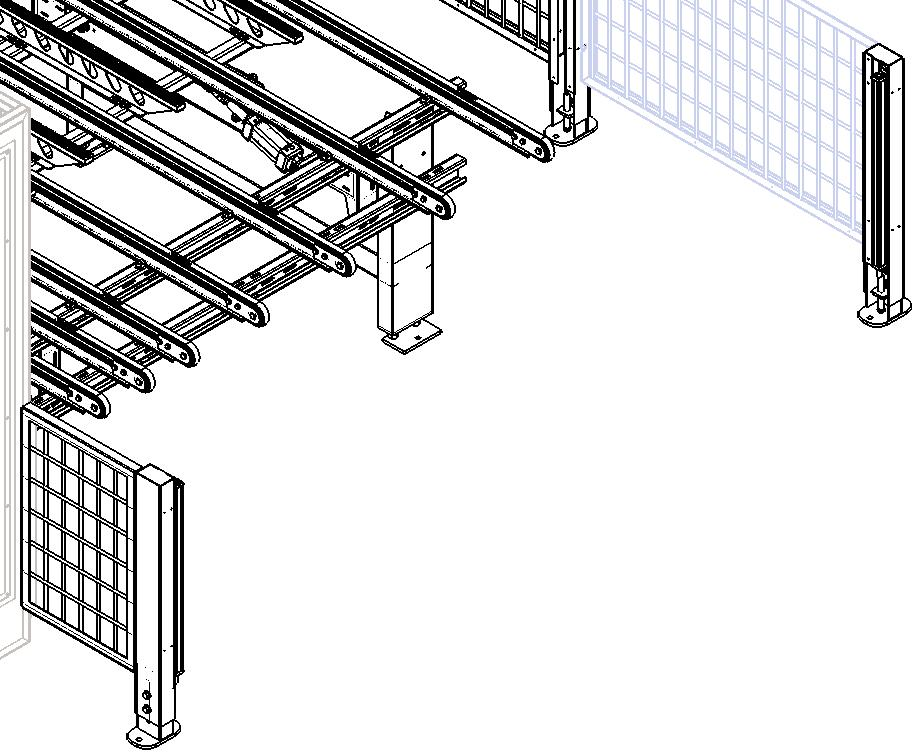

Safety Grating

Front loading area.

Side discharging area.

When a foreign object or worker is within the grating range, the machine will alarm and stop immediately.

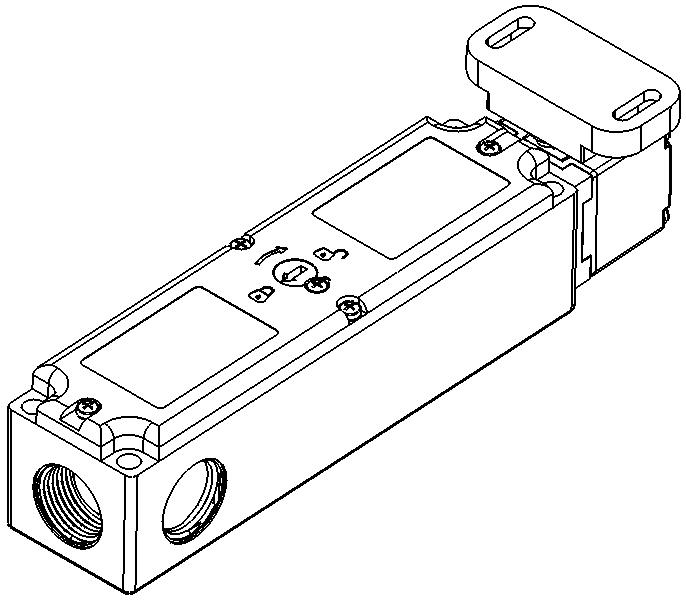

Safety Interlock

front guard door equips with one.

left and right side doors each equip with one.

It will lock the door for 2 minutes after triggering the emergency stop.

The spindle will stop immediately when the doors open, and won’t delay due to power failure of the brake system or inverter.

Emergency Stop

The equipment feed beam guard is provided with one piece at each end, and with an emergency stop sign.

Emergency Stop

There is an emergency stop pull rod and an emergency stop sign on the lower side of the air-floating table.

Emergency Stop

The operation screen button panel is equipped with an emergency stop switch and an emergency stop sign.

Separate Circuit Breaker

Equipped with an isolating switch with a metal extension rod, the electrical box door can only be opened after the power is cut off.

Technical Specifications

| Processing Size Range | Min. Width | 50mm |

| Max. Width | 1200mm | |

| Max. Length | 250mm | |

| Min. Length | 2800mm | |

| Panel Thickness | 10mm | |

| Panel Thickness | 60mm | |

| Max. Positioning Speed | X axis: | 130m/min |

| Y axis: | 85m/min | |

| Z axis: | 30m/min | |

| U axis | 130m/min | |

| V axis | 80m/min | |

| Waxis | 30m/min | |

| A axis: | 30m/min | |

| Y2 axis: | 85m/min | |

| Z2 axis: | 30m/min | |

| Drilling Box Configuration | Top drilling box | Vertical:16*2pcs Horizontal:8pcs*2 |

| Bottom drilling box | Vertical:12pcs | |

| Motor power | 2.2kw*3 | |

| Motor speed | 4500rpm | |

| Processing Size Range | Quantity | Top:1 pc Bottom:1pc |

| Spindle power | 3.5kw | |

| Tool holder diameter | 1/2” | |

| Spindle speed | 18000rmp | |

| Other Data: | Height of working table | 960mm |

| Total Power | 22.22KW | |

| Working air pressure | 0.7-0.8Mpa |

Applications

6 sides servo drilling, grooving, meet all kinds of furniture production needs.