SKG-812S

SKG-812S

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

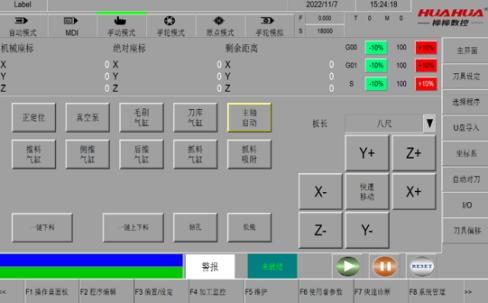

Color Screen Display

Using color screen display with keyboard.

Safe and reliable operation.

Simple and friendly interface.

Complete operating tips, concise and clear.

Syntec Control System

Data can be loaded by CAD, quick and convenient operation.

Match with user production design management software, no need to enter data independently.

Intelligent processing list, load the file for one time and will continuously processing to end.

Syntec Driver

Powerful multi-axis CNC system.

More comprehensive control and monitoring of machines.

Quickly resolve machine failures and reduce failure rates.

Real-time power outage data storage and remote machine diagnosis.

Spindle

9kw high precision spindle, ensuring stable processing.

Tool Magazine

12 tools linear type tool magazine.

Automatic tool change according to set program.

Proximity principle to quickly complete the tool changing process.

Automatic Tool Setting

Easier to operate the machine.

Make sure the precision.

Drive Motor

High-performance servo motor drive.

Accurately respond to control signals.

Ensure cutting accuracy.

Planetary Reducer

High precision, high torque.

Backlash less than 3 arc minutes, accurate positioning.

Use integral roller bearings.

The main bearing adopts tapered needle roller bearing to ensure the processing speed and stability of the equipment.

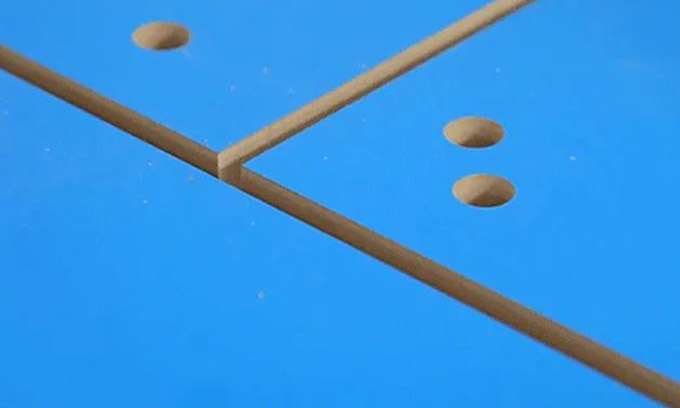

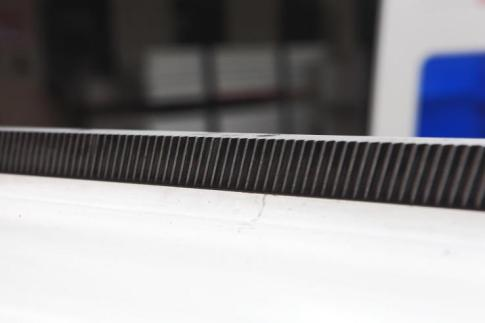

X/Y Axis Transmission

Precision helical rack.

Reasonable design leads to smooth flow.

High strength and rigidity, stable properties.

Sufficient toughness and smooth operation.

Z Axis Transmission

High precision ball screw transmission.

The error is within 0.05~0.1mm.

The cumulative error is within ±0.1mm.

Greatly improve the precision of the whole machine.

High Precision Guide Rail

Using 30# guide rails to ensure equipment accuracy and stability.

Large specifications, large contact surface, strong load-carrying capacity.

The guide rail mounting surfaces are all welded with steel strips, increase the bolt confinement depth to increase the load-bearing capacity.

EUROVAC Vacuum Pump

Dry vacuum pump, longer service life.

High efficiency, low noise.

Low temperature rises, smooth operation.

Strong adsorption capacity.

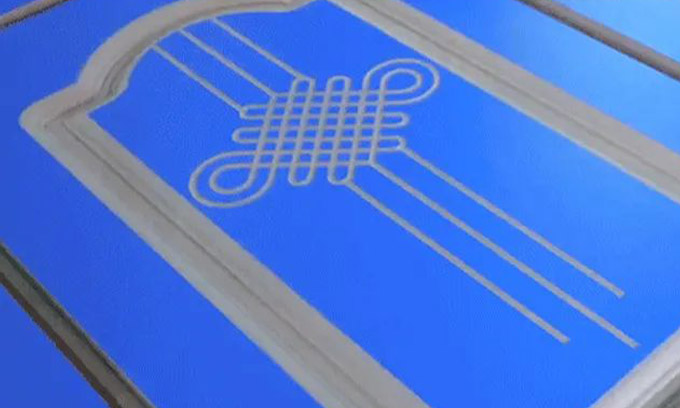

Drilling Head & Pressure Roller

9 vertical drill bits

Pressure roller can prevent panels from skewing, ensuring processing accuracy.

Customized Working Area

Customize the wokring area according to your request, such as 6*9 ft (1830*2745mm), 5*10ft (1525*3050mm) and so on.

Technical Specifications

| Model | SKG-812S |

| Working Area | 2800*1300mm |

| Max. Moving Speed of X axis | 80m/min |

| Max. Moving Speed of Y axis | 80m/min |

| Max. Moving Speed of Z axis | 20m/min |

| Spindle quantity | 1 |

| Spindle power | 9KW |

| Drilling Unit | Option |

| Vacuum power | 7.5KW |

| Vacuum power air volume | 250m³/h |

| Total power | 20.5kw |

| Machine size | 4366*3340*2901mm |

Applications

Precision cutting, drilling and milling combined in one machine. Achieve flexible production.