SDN-649

SDN-649

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

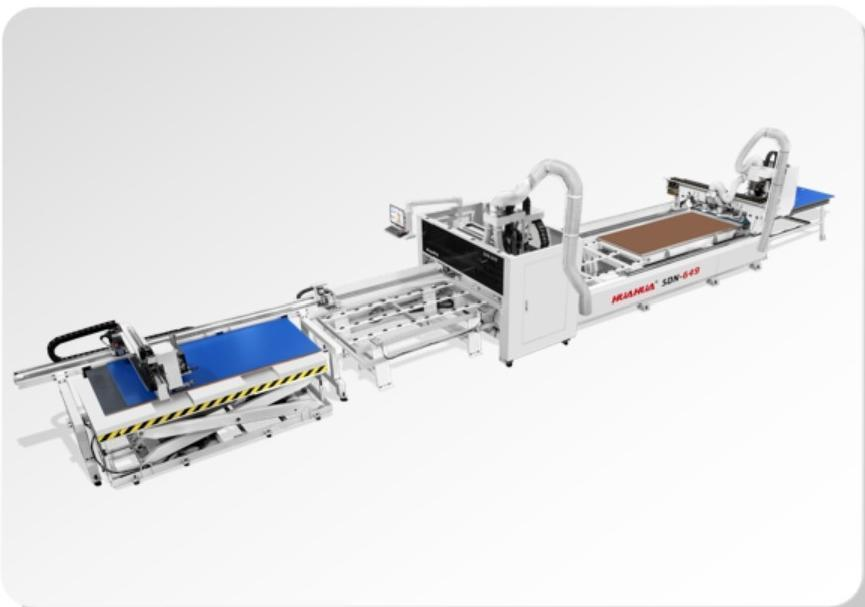

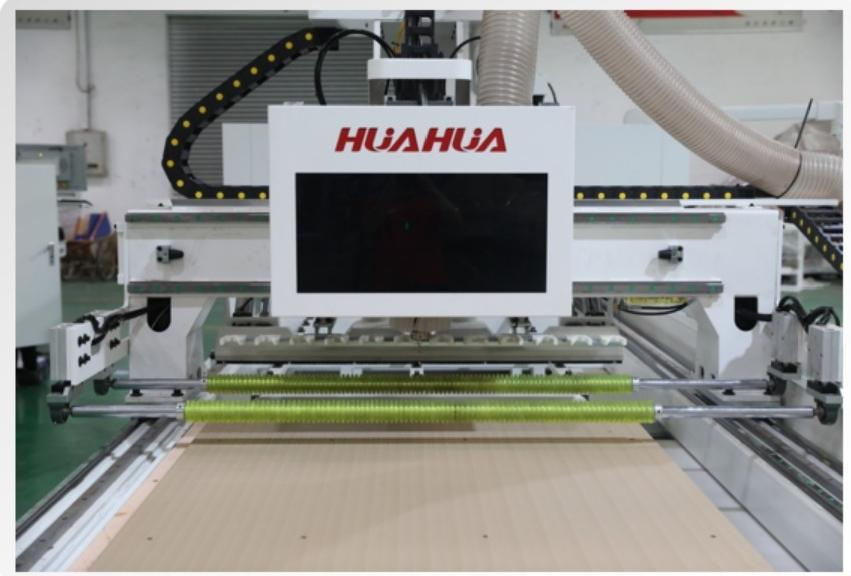

4*8 feet & 4*9 feet panel processing

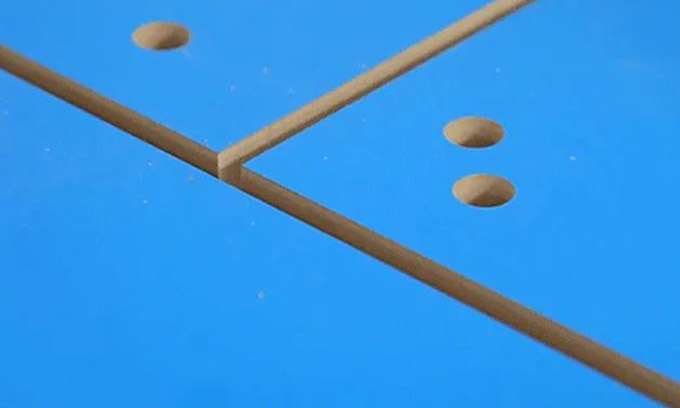

For 4*8 feet & 4*9 feet panel, drilling first and then cutting, reduce the stress deformation after cutting that may cause hole position deviation.

3 workstations process simutaneously

The three workstations can work simultaneously and automatically wait, improving production efficiency. It is suitable for cutting materials of various sizes and irregular shapes, and can efficiently complete various special furniture customization. The drilling and cutting are integrated, and there is no need to press the material in the air which may cause angle errors. The same track benchmark ensures processing accuracy.

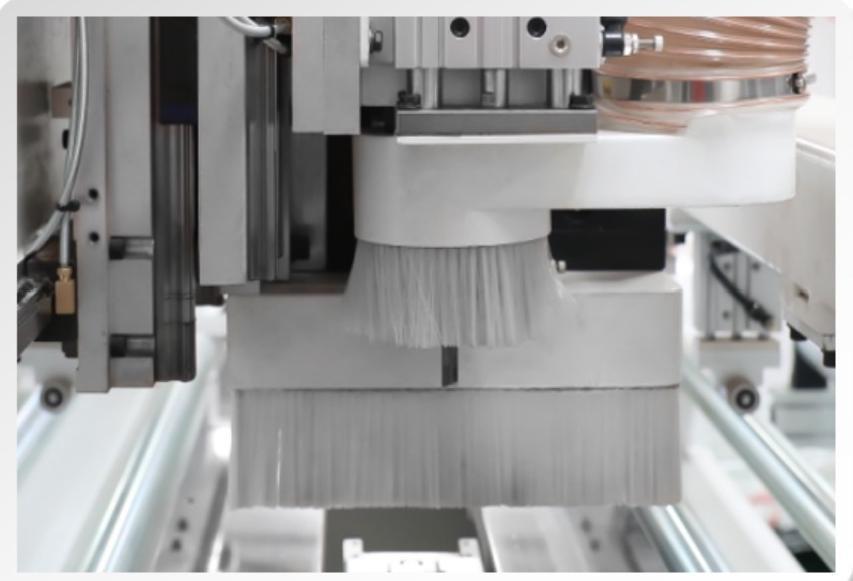

Intelligent pressing panel

Six groups of pressing wheels in total, keep straight panel processing,ensuring the processing accuracy of panel.

High precision drilling head

One high-precision drilling head for each up and down. efficient processing, can process panel of width 1220mm and length 2440- 2800mm.

Integrated frame

The integrated frame is processed by precision CNC equipment, with a simple structure, easy to maintain and clean. After annealing, it is durable and not easy to deform, maintaining long-term operation stability and processing accuracy.

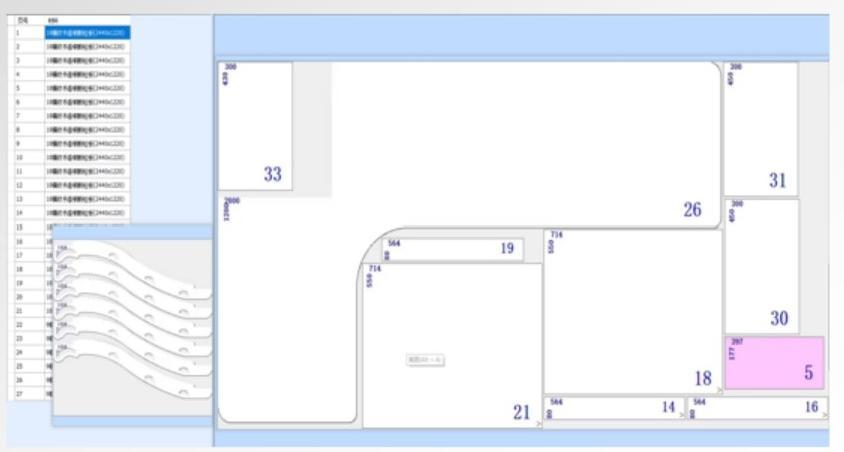

Self-developed nesting software

The order splitting system, optimization system, order tracking, packaging system and other important production links are connected in series in one software system to achieve universal data synchronization, reduce error rate and reduce operation.

Small aperture dust blowing system

From drilling to cutting, small aperture dust blowing system enhances the adsorption of cutting.

Integrated electrical box and rack

The integrated electrical box and frame prevent dragging unchanged and reduce wire folding.

Syntec system

Syntec system, better compatibility, stronger matching and lower failure rate.

21-inch large display screen

21-inch large display screen, simple operation, easy to learn and use, and can also be updated autonomously through remote control, convenient for maintenance and upgrade.

Automatic labeling

Automatic labeling and intelligent panel detection make the operation more humane. The servo motor and centralized oiling device make the equipment run more smoothly.

Fixed integrated worktable

Fixed integrated worktable can maintain stable and accurate processing even in long-term processing, with longer service life. The pressure roller can assist in pressing the material to straighten the deformed panel, and the processing accuracy is higher.

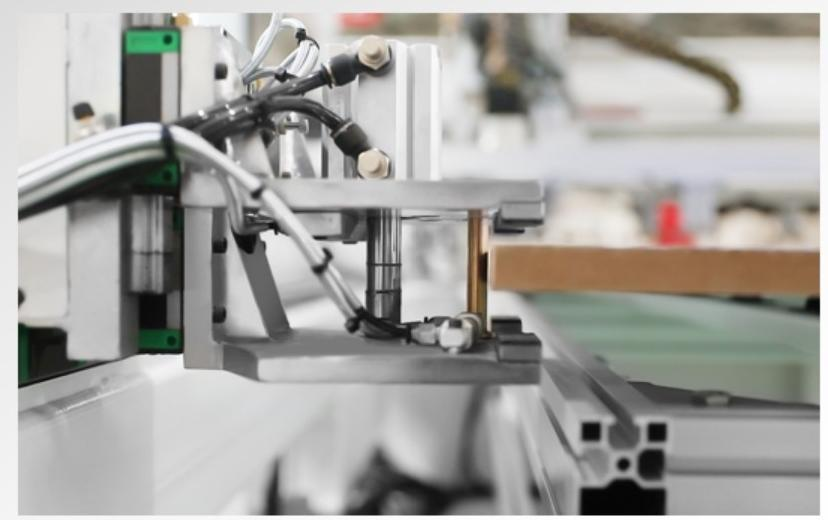

Double clamps

According to the computer drilling program, the panel feeding and positioning are automatically controlled to improve the drilling accuracy. It effectively prevents the edge band from being scratched. The clamp is positioned in a movable manner. There is no need to press the material in the air which may cause angle errors. When the clamp drags the panel to the worktable, it can adapt to the table height.

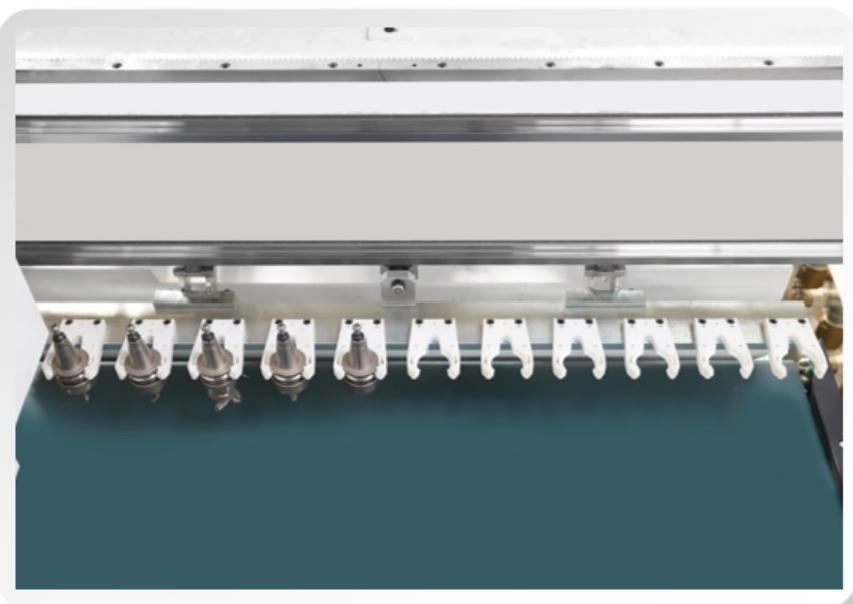

Linear type tool magazine with 12 tools

Linear type tool magazine with 12 tools,one tool for one craft, automatic tool change without waiting.

Dust blowing & dust sunction

Different processing steps of the drilling head and the spindle correspond to different dust suction ports, which can be turned on and off at any time to reduce energy consumption. Dust blowing + dust suction has a strong effect in removing dust and wood chips.

Automatic loading and unloading

The lifting platform rises automatically, which is convenient for equipment loading and saves labor costs. The belt conveyor unloads materials and cooperates with the push plate to unload materials, reducing manual operations.

Large and small table design

The cutting table adopts large and small table designs. The small table can automatically avoid clamps by controlling the lifting and lowering, so that drilling and cutting can be integrated with the track.

Technical Specifications

| Model | SDN-649 |

| Panel width | 1200mm |

| Panel length 1 | 2800mm |

| Panel length 2 | 2400mm |

| Max. panel thickness | 25mm |

| Mini. panel thickness | 12mm |

| Height of working table | 900mm |

| Working voltage | 380V/50Hz |

| Working pressure | 0.7-0.8Mpa |

| Dust suction port | 110mm*2145mm*1195mm*2 |

| Total power | 42.1kw |

| Size | 16200mm*2370mm*2960mm |

Applications

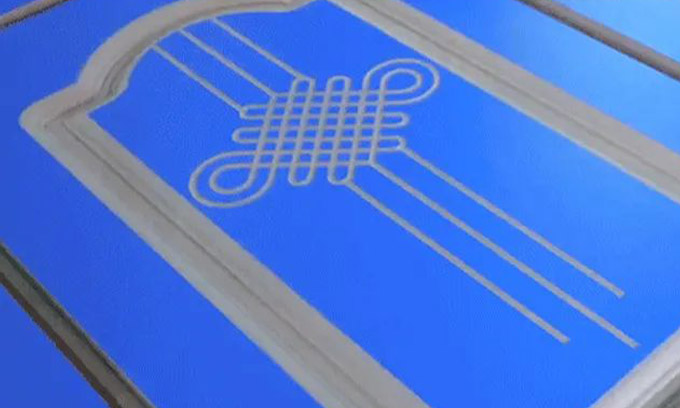

Precision cutting, drilling and milling combined in one machine. Achieve flexible production.