In the fast-paced world of manufacturing, efficiency and precision are paramount. At HUAHUA CNC, we are dedicated to delivering reliable solutions that enhance your production capabilities. Our latest edge banders, particularly the HH-406RP, exemplify our dedication to quality and innovation.

Exceptional Specifications for Optimal Performance

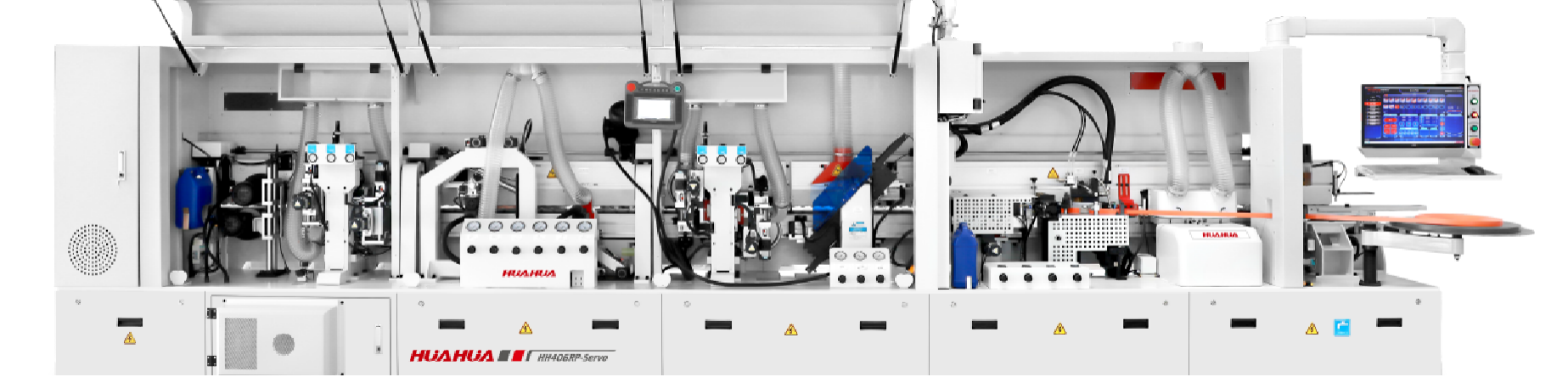

The HH-406RP edge bander boasts impressive specifications that cater to the needs of modern manufacturing. With an overall size of 7,035*730*2,170 mm and a total power output of 25 kW, this machine is designed to handle a variety of tasks with ease. The working pressure of 0.65MPa ensures optimal performance during operation, allowing for seamless edge banding processes. This combination of size, power, and pressure makes the HH-406RP an essential addition to any workshop looking to enhance efficiency and output.

User-Friendly Features for Every Operator

One of the standout features of our edge banders is the large computer screen that simplifies operation. We understand that a user-friendly interface can significantly impact productivity, which is why we designed the HH-406RP with a simple interface and complete operating instructions. This makes it easy for operators of all skill levels to manage the machine effectively. Additionally, the single-arm suspension design saves valuable space in your workshop, allowing for a more organized and efficient work environment.

Precision is critical in edge banding, and the high-precision control of the servo motor in the HH-406RP ensures accurate positioning of the panel during the edge banding process. This feature not only enhances the quality of the finished product but also minimizes waste, making it a cost-effective solution for your business.

Enhanced Functionality for Superior Edge Banding

Our edge banders are equipped with advanced technology designed to improve functionality and output. The spiral dust collection system offers a better effect, ensuring a cleaner workspace while reducing downtime for maintenance. Additionally, the HH-406RP is powered by a 7kw high-power motor, which provides the strength needed to tackle even the toughest jobs.

The machine is capable of milling panel surface corrugations and expanded edges, with a maximum pre-milling height of 40mm (optional 65mm). This versatility allows users to work with a range of materials and thicknesses, making it an ideal choice for businesses of all sizes. Moreover, the preheating feature for panel edges effectively prevents cracking due to significant temperature differences, ensuring the integrity of your materials throughout the edge banding process.

Conclusion

At HUAHUA CNC, we believe that investing in quality edge banders is essential for any manufacturing operation looking to improve efficiency and product quality. The HH-406RP combines powerful specifications with user-friendly features and advanced technology, making it a standout choice for businesses aiming to thrive in a competitive market. With our commitment to innovation and excellence, we are confident that our edge banders will elevate your production capabilities and set your business on a path to success.

If you’re ready to transform your edge banding process, we invite you to explore the HH-406RP and see how HUAHUA CNC can support your manufacturing goals. Together, let’s redefine what’s possible in edge banding technology.