We at HUAHUA CNC focus on delivering advanced machinery solutions that help our partners optimize production and improve precision in panel furniture manufacturing. One of the key innovations in our lineup is the servo motor machine, which enhances speed, accuracy, and control across various woodworking processes. When paired with our edge banding machine, these systems form a complete production solution, allowing businesses to achieve consistent results while maintaining high efficiency.

Understanding the Role of Servo Motors in Modern Machinery

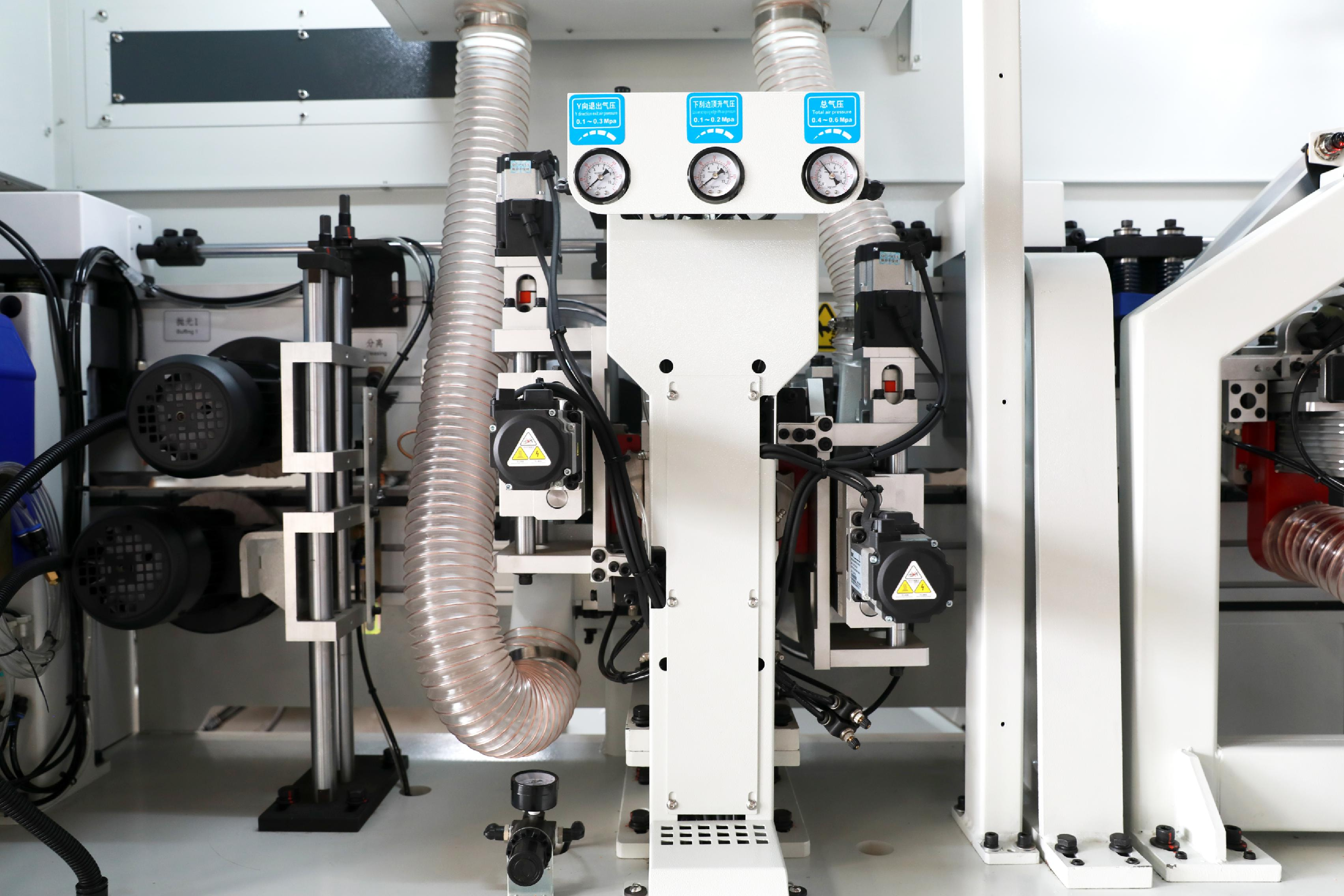

A servo motor machine is designed to provide precise motion control and powerful torque, enabling complex operations such as multi-radius scraping and trimming. On our HH-406RP model, the servo motor drives the panel scraper to ensure that wave marks caused by rotation are effectively smoothed on both sides of the panel. This technology allows the upper and lower surfaces to achieve a polished, professional finish, improving overall quality without additional manual labor. By incorporating servo motors, we ensure our machines can handle various materials and thicknesses while maintaining consistent results across production batches.

Integrating Servo Motors with Edge Banding Solutions

Our edge banding machine is optimized to work seamlessly with servo motor-driven systems. The precise motion control provided by the servo motor allows accurate positioning and uniform pressure during the banding process. As a result, furniture panels are sealed cleanly and consistently, reducing waste and increasing throughput. We provide tailored solutions for different markets, offering free consultations on full-factory layouts to maximize output and efficiency. Our ability to customize machine dimensions and features based on local panel sizes and furniture types ensures that our partners receive equipment that perfectly fits their production needs.

Supporting Our Global Partners

We understand that efficient operation goes beyond hardware. For our overseas clients, we provide comprehensive support including detailed installation videos, 24-hour after-sales service, and a dedicated service group chat to quickly resolve any issues. Our engineers can also visit client sites to assist with installation, commissioning, and staff training, ensuring smooth operation from day one. Standard machines typically have a delivery time of around 30 days, while customized solutions or complete factory setups are scheduled based on project requirements. For those interested in becoming a local partner, we currently have agents in some countries and are actively seeking global collaboration opportunities.

Conclusion

The combination of HUAHUA CNC expertise, servo motor machine technology, and our edge banding machine capabilities provides a powerful platform for efficient, high-quality panel furniture production. By emphasizing precision, consistency, and adaptability, we help our partners meet the demands of modern manufacturing while maintaining exceptional product quality. Our commitment to innovation, customized solutions, and comprehensive support ensures that working with HUAHUA CNC is a collaborative and growth-oriented experience.