High-quality edge finishing is a critical factor in panel furniture production, directly impacting both the visual appeal and long-term durability of the products. At HUAHUA CNC, we understand that manufacturers need precision, consistency, and efficiency to remain competitive. That’s why we provide professional edge banding machine solutions specifically designed for industrial-scale furniture production. These machines streamline the process of trimming and finishing panel edges, ensuring consistent quality across every panel while reducing labor requirements. By adopting our advanced equipment, furniture manufacturers can enhance production efficiency without compromising on craftsmanship or material integrity.

The Role of Edge Banding Machines in Modern Manufacturing

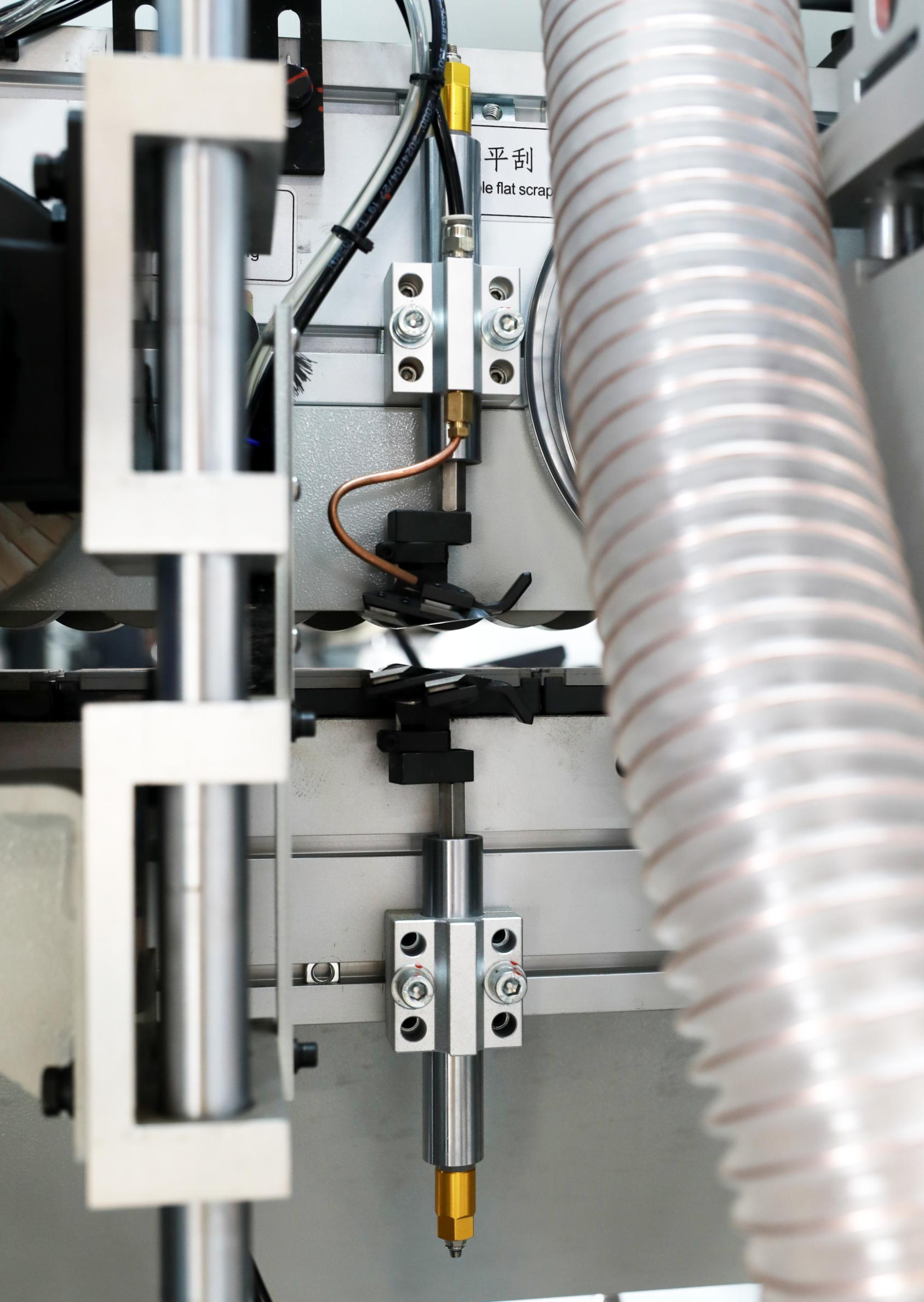

A servo edge banding machine is an essential tool for furniture factories, providing accurate control over edge trimming and finishing tasks. The servo-driven system allows precise movement and constant pressure, ensuring uniform application of edge banding materials on panels of different sizes and thicknesses. At HUAHUA CNC, our machines also feature Floating Flat Scraping technology, which removes residual glue from the upper and lower surfaces of the panel edges. This prevents glue from sticking to polishing wheels, reduces the frequency of wheel replacements, and lowers overall maintenance costs. Such features make our machines reliable and ideal for high-volume production environments, allowing agents and partners to deliver consistent quality to their customers.

Comprehensive Support and Collaboration with HUAHUA CNC

We offer more than just machinery; we provide a complete support system for our partners. Our team delivers free consultation for factory layout optimization and full production line planning, helping agents design highly efficient workflows. HUAHUA CNC provides on-site installation guidance and product training for all partners, ensuring smooth integration of machines into existing operations. For overseas clients, we supply detailed installation videos and establish dedicated after-sales group chats to address issues in real-time. Standard models typically ship within 30 days, while fully customized machines or integrated production lines may require additional time depending on specific requirements.

Advantages for Agents and Distributors

Agents working with HUAHUA CNC benefit from high-quality, patented machines, flexible customization options, and competitive pricing. Our machines are designed to accommodate different panel sizes, furniture types, and regional requirements. We hold both domestic 3C and European CE certifications, providing confidence in quality and compliance with international standards. We actively seek global partners and support them with marketing materials, promotional campaigns, and guidance on selling and servicing machines locally. Agents can rely on our engineering team to provide technical support and training to their own staff, enabling them to offer high-quality services in their regions.

Conclusion

For manufacturers and agents seeking precise, efficient, and reliable edge finishing, the edge banding machine and servo edge banding machine from HUAHUA CNC deliver exceptional value. By combining innovative technology, multiple patented designs, professional training, and comprehensive after-sales support, we ensure every panel meets the highest standards. Partnering with HUAHUA CNC allows businesses to increase production efficiency, reduce maintenance challenges, and expand their capabilities in the competitive furniture manufacturing market. With our machines and support, agents can confidently provide clients with reliable, high-quality solutions that enhance both productivity and profitability.