In modern woodworking, efficiency and precision are essential for businesses producing panel furniture at scale. At HUAHUA CNC, we have continually focused on providing edge banding machine solutions that meet the needs of professional manufacturers. Our PVC edge banding machine lineup is designed to support enterprises seeking reliable, high-quality, and flexible production capabilities. By integrating advanced technology, we ensure that clients achieve consistent finishes and streamlined operations across their workshops.

Understanding PVC Edge Banding

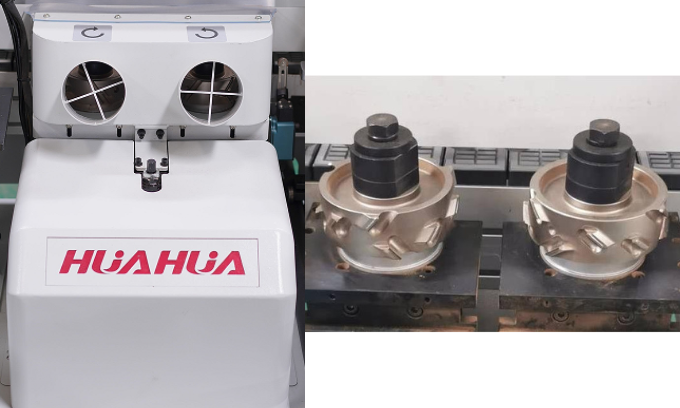

A PVC edge banding machine is specialized equipment used to apply PVC or other synthetic edging strips to the raw edges of panels, enhancing both appearance and durability. At HUAHUA CNC, we emphasize precision and flexibility in our edge banding machine designs, which are suitable for a wide range of board sizes and furniture types. Our HH 506R PVC edge banding machine combines automated feeding, heating, and trimming processes to deliver smooth, uniform edges efficiently. For businesses aiming to maintain consistent product quality while optimizing labor usage, this equipment provides a reliable solution.

Benefits for Partners and Manufacturers

We recognize that our clients often operate in competitive markets and need more than just machines—they require support and customization. That is why HUAHUA CNC offers free consultation on full production lines, helping manufacturers design layouts that maximize output and material efficiency. Enterprises frequently ask us about installation, delivery, and after-sales service. We address these by providing detailed installation videos, establishing professional support groups for real-time troubleshooting, and arranging on-site engineers when necessary. Standard machines typically have a delivery time of around 30 days, while customized models or full-line solutions depend on specific project requirements. For companies seeking to become local agents, we maintain a global network and welcome inquiries for partnership opportunities.

Commitment to Quality and Innovation

Our edge banding machine solutions are developed by a dynamic R&D team led by German engineers, aligning with European technological standards. We maintain dedicated production facilities for critical machine components, ensuring stability and high quality. HUAHUA CNC holds both domestic 3C certification and European CE certification, reflecting our commitment to safety and reliability. The design of our PVC edge banding machine features multiple appearance patents, combining functional efficiency with visual appeal. Clients also benefit from flexible options, including low minimum order quantities, tailored customization for local panel sizes, and ongoing technical support.

Conclusion

Investing in advanced edge banding machine technology is vital for furniture manufacturers aiming for consistency, efficiency, and product quality. At HUAHUA CNC, we provide professional machinery, expert consultation, and comprehensive after-sales service, supporting both direct manufacturing clients and local agents seeking collaboration. Our PVC edge banding machine solutions exemplify our dedication to combining innovation, quality, and customer-oriented service, helping partners achieve optimal results in modern panel furniture production.