At HUAHUA CNC, we pride ourselves on delivering precision-engineered solutions that meet the diverse needs of our clients. With our advanced technologies and commitment to quality, we ensure that every product we manufacture stands up to the highest standards in the industry. In this article, we’ll delve into our processes, the technology we utilize, and how we ensure exceptional results for our CNC panel saws and other machinery.

Our Commitment to Quality and Precision

One of the key aspects of our manufacturing process is the attention we pay to stress management in our materials. After the welding of the frame is completed, it is placed for one month, and then heat treated. This process is essential to eliminate the residual stress generated during the machining process. By changing the crystal structure inside the material, we enhance the stability of the subject. Following this initial treatment, the frame undergoes an additional six months of careful monitoring and adjustment before it is sent to the machining center for precision machining. This meticulous approach guarantees that our CNC panel saws perform reliably under various conditions.

Cutting-Edge Technology with FX3U Japan Mitsubishi PLC

To achieve our high standards of precision, we integrate trusted technology into our CNC panel saws. A prime example is the FX3U Japan Mitsubishi PLC, a third-generation micro programmable controller that boasts impressive features. With built-in large-capacity RAM memory of up to 64K and one of the industry’s highest levels of high-speed processing at 0.065μS per basic command, this controller enhances our machining capabilities significantly. Additionally, it includes an independent 3-axis 100kHz positioning function (transistor output type), which allows for remarkable accuracy and efficiency in our operations. This technology is instrumental in ensuring that our CNC panel saws can meet the demands of precision cutting with ease.

The Versatility of HP3318 in Our Offerings

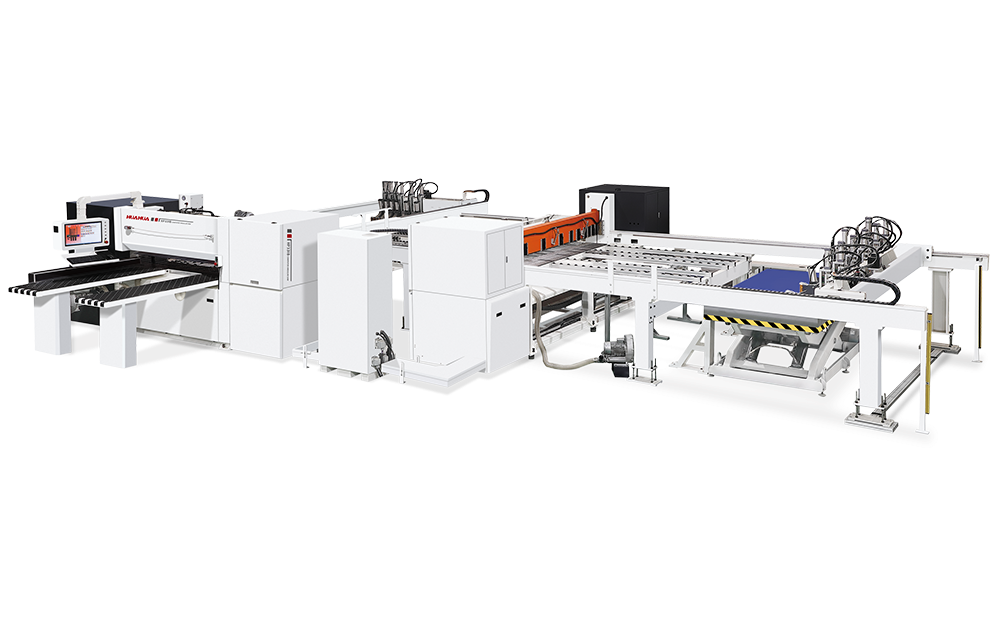

Another critical component of our machinery lineup is the HP3318, designed for maximum versatility and efficiency. This CNC panel saw features a maximum cutting length for both vertical and horizontal cutting, making it ideal for various applications. Its computer angular saw capabilities allow for precise angular cuts, which are essential for intricate designs. The machine size of 15315*7988*2060mm provides ample workspace, accommodating large materials without compromising precision. By incorporating the HP3318 into our production line, we ensure that our CNC panel saws can handle a wide range of projects, from simple cuts to complex designs.

Conclusion

At HUAHUA CNC, we are committed to pushing the boundaries of what is possible in precision engineering. Our comprehensive approach—ranging from stress management post-welding to the integration of advanced technology like the FX3U Japan Mitsubishi PLC and the HP3318—ensures that our CNC panel saw are among the best in the market. As we continue to innovate and refine our processes, we remain dedicated to delivering exceptional products that meet the evolving needs of our clients. Join us on this journey as we redefine the standards of quality and precision in the CNC industry.