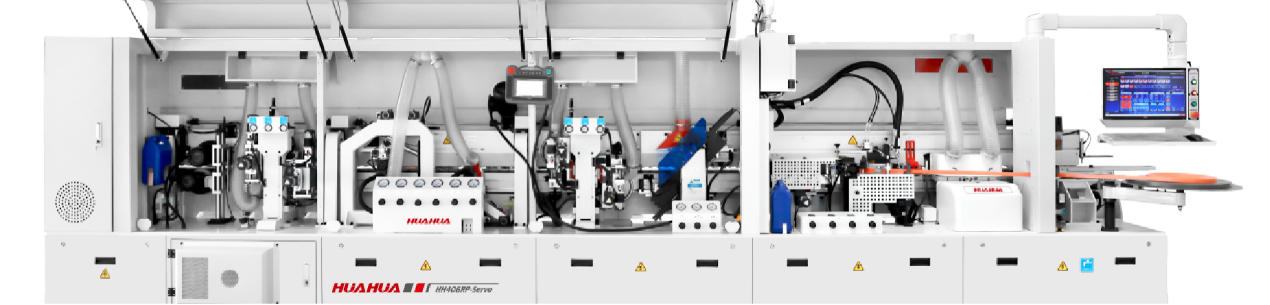

Here at HUAHUA CNC, we’re dedicated to supplying manufacturers with cutting-edge woodworking technology that boosts efficiency, accuracy, and operational expenses over the long run. Our continuous focus on innovation has led us to develop the HH-406RP, a high-performance edge banding machine engineered for superior trimming, scraping, and finishing results. With servo-controlled systems and optimized edge processing features, the HH-406RP enables businesses to achieve cleaner, smoother, and more consistent finishes across a wide range of panel applications.

Servo Multi-Radius Fine Trimming

The HH-406RP features a servo multi-radius fine trimming function, designed to deliver precise results on panel edges. By adopting large and small discs with automatic tracking and a high-frequency, high-speed motor structure, the system efficiently trims bonded tapes on the upper and lower sides of panels. At the same time, it mills the edges into a neat R-shape finish. This combination ensures smooth transitions, consistent accuracy, and reduced manual involvement, making the HH-406RP a reliable solution for high-volume production lines.

Servo Multi-Radius Scraping

To further improve surface quality, the HH-406RP includes a servo multi-radius scraping system. The trimming tool on both sides of the panel effectively scrapes away the wave marks that can occur during rotational processing. This results in cleaner, smoother, and more professional finishes on the upper and lower panel edges. By eliminating tool marks and imperfections, this function enhances overall product quality and reduces the need for additional manual finishing, helping manufacturers streamline workflows while maintaining consistent standards.

Floating Flat Scraping for Glue Removal

Another advanced feature of the HH-406RP is its floating flat scraping system, designed to handle glue residue with efficiency. This function removes the remaining glue extruded from the joints of the upper and lower planes of the edge banding attached to the panel. By keeping the panel surface clean, it reduces the likelihood of glue sticking to the buffing wheel and lowers the frequency of polishing wheel replacement. This not only minimizes maintenance requirements but also helps manufacturers maintain smoother operations and extend equipment life.

Conclusion

At HUAHUA CNC, we continue to deliver equipment that combines precision, durability, and user-focused design. The HH-406RP embodies these values with its servo multi-radius fine trimming, advanced scraping systems, and floating flat scraping technology. As a trusted provider of edge banding machine solutions, we empower manufacturers to achieve higher accuracy, reduced maintenance, and consistent product quality. By choosing HUAHUA CNC, businesses gain a long-term partner in efficiency and innovation.