Precision and efficiency are crucial for modern woodworking production. At HUAHUA CNC, we focus on providing practical solutions for furniture manufacturers who need consistent quality and optimized output. Our expertise with cnc drilling machine and cnc boring machine technology allows us to support clients in streamlining their production lines while maintaining accuracy and reliability.

Programming a CNC Dowel Insertion Machine

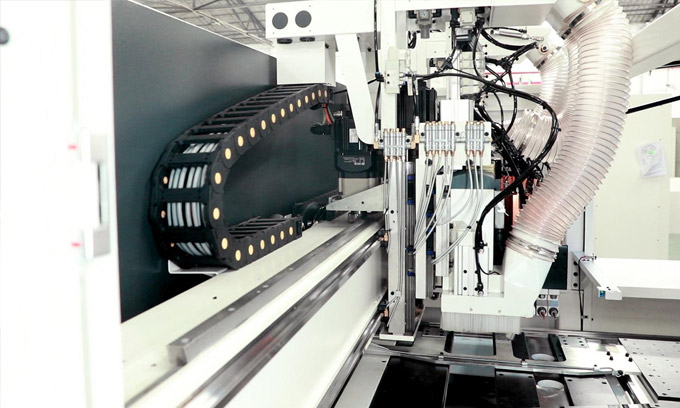

Programming a cnc drilling machine for dowel insertion begins with understanding the machine’s control system and mechanical setup. Our equipment, such as the HUAHUA SKH-612NS, utilizes rack and pinion transmission, ensuring both top and bottom drilling heads move with high precision. This design reduces misalignment during dowel insertion, providing consistent and repeatable results. When setting up the program, it is essential to define drilling coordinates, insertion depth, and dowel spacing according to the furniture panel dimensions. We provide free consultation to assist clients in designing the most efficient layout for their production line, ensuring high productivity from the start.

Optimizing Operations with CNC Boring Machines

Our cnc boring machine solutions are designed to handle multiple panel sizes and furniture types. We understand that our international partners often have unique board dimensions, which is why we offer machine customization to suit different market requirements. Our engineers guide clients through installation and commissioning, either remotely or on-site, and provide 24-hour support through dedicated service chat groups. This approach ensures that common concerns—such as troubleshooting, machine calibration, and dowel alignment—are resolved quickly and professionally.

Advantages of Choosing HUAHUA CNC

We take pride in combining technology, design, and service. HUAHUA CNC is recognized as one of the three major Chinese manufacturers of panel furniture equipment, holding multiple appearance design patents. Our machines are built to deliver high-quality performance, supported by 3C and CE certifications. For B2B partners and potential agents, we offer competitive pricing, low minimum order quantities, and optional promotional support. By leveraging our passionate R&D team, led by German engineers, we ensure that our cnc drilling machine and cnc boring machine solutions incorporate advanced European technology while maintaining reliable production stability through our dedicated rack manufacturing base.

Conclusion

Programming a dowel insertion machine requires precision, planning, and support from an experienced manufacturer. With HUAHUA CNC, clients gain access to tailored solutions, professional guidance, and reliable cnc drilling machine and cnc boring machine equipment. We continuously focus on enhancing service, optimizing machine performance, and helping our partners establish efficient furniture production lines. For companies seeking a long-term partner in woodworking automation, we provide both technical expertise and comprehensive after-sales support, ensuring seamless integration and successful operation worldwide.