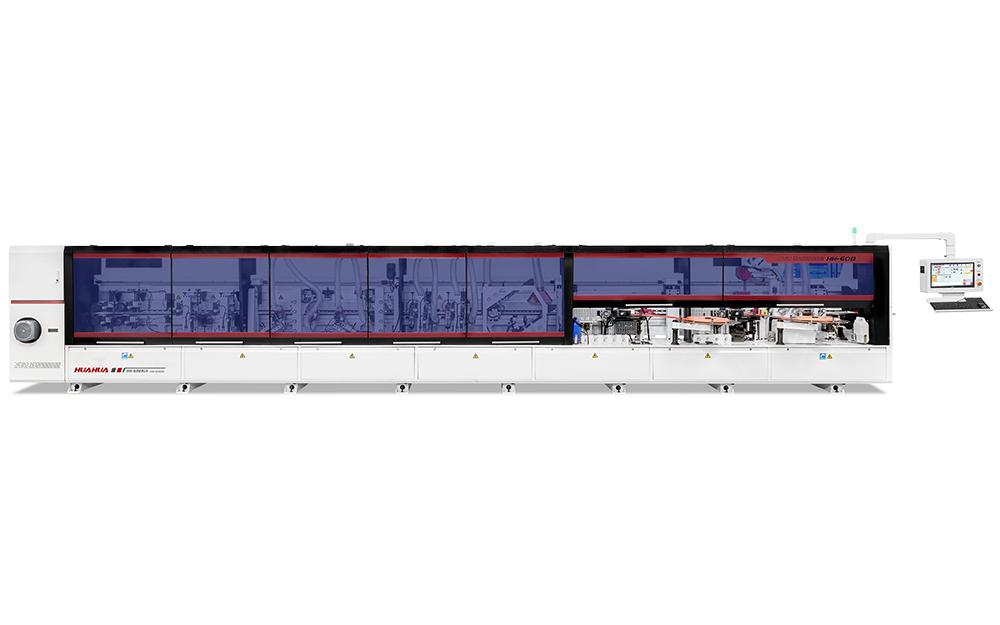

At HUAHUA CNC, we believe that every step in the edge processing journey matters. That’s why our edge banding machines are engineered with precision, performance, and long-term reliability in mind. We focus on optimizing every detail—from pre-milling to polishing—to help manufacturers produce high-quality panel furniture that stands out in today’s competitive market. With innovative technology and thoughtful design, our equipment ensures each panel edge is smooth, sealed, and showroom-ready.

Well Pre-Mill, Half Done

We start where it matters most—at the edge. Our edge banding machine is equipped with a powerful pre-milling unit that grinds the edges of panels before glue application. This crucial first step removes surface imperfections, guarantees a clean bonding surface, and ensures the tape adheres tightly to the panel. Pre-milling not only improves the visual finish but also enhances the overall structural integrity of the final product. At HUAHUA, we know that a good beginning leads to a perfect result.

Water-Proof PUR Glue for Long-Lasting Protection

Glue quality is vital for durable edge banding. That’s why our machines utilize water-proof and damp-proof PUR (polyurethane resin) glue in the gluing device. This high-performance adhesive forms a strong bond that resists moisture, making it ideal for kitchen and bathroom furniture where water exposure is common. By offering enhanced protection against swelling and delamination, our PUR glue system extends the life of your wood panels and increases customer satisfaction.

Auto-Track Trimming for a Seamless Finish

To ensure a flawless finish, our edge banding machine includes an automatic tracking trimming system. Dual trimming discs accurately follow the panel’s contour to remove excess glue and tape, leaving a clean and polished appearance. This automation minimizes manual touch-ups and improves processing speed—making it ideal for mass production. The result is a smoother, more consistent edge that meets the high standards of the end market.

Corner Rounding & Polishing for a Premium Look

The final impression of a product often lies in its smallest details. That’s why we incorporate a corner rounding device and cloth polishing wheels into our machines. The corner rounding unit transforms sharp tape ends into smooth R-shaped arcs, enhancing both safety and aesthetics. Meanwhile, the polishing wheels buff the edge to a high-quality finish, removing any remaining glue and leaving a professional shine. These additions take your panel furniture from good to great.

Conclusion

At HUAHUA CNC, every detailed optimization perfects the edge banding process. Our edge banding machines are designed not only for speed and efficiency but also for precision and craftsmanship. From pre-milling to polishing, each feature works together to deliver flawless results every time. Trust HUAHUA CNC to upgrade your edge banding process and help you meet the highest standards in panel furniture manufacturing.