An essential component of any edge banding machine is its glue application system, and the HUAHUA CNC HH-406RP does not disappoint. Featuring a double-color clean-free glue pot, our servo edge banding machine is designed to minimize the need for frequent cleaning, thereby saving us both time and labor costs without compromising quality.

Versatile Glue Application for Various Projects

The 2kg multifunctional glue machine is capable of using EVA glue, providing us with the flexibility needed for various projects. This versatility allows us to select the best adhesive for our specific needs, ensuring a strong bond that enhances the durability of the finished product. The clean-free glue pot design is particularly beneficial, allowing us to focus more on production and less on maintenance, which is crucial in a busy workshop environment.

Consistent Application for High-Quality Results

Additionally, the glue system is designed for efficiency, ensuring that the adhesive is applied evenly and consistently. This consistency is vital for achieving high-quality edge banding results, as it prevents issues such as glue seepage or uneven application, which can compromise the integrity of the edge. By maintaining high standards in our glue application, we enhance the overall quality of our woodworking projects.

Proactive Glue Management for Optimal Performance

The servo edge banding machine also includes features that allow us to monitor glue levels and make timely adjustments as needed. This proactive approach to glue management ensures that we maintain optimal performance throughout the edge banding process. By ensuring that our glue system operates smoothly, we can focus on delivering exceptional products to our clients.

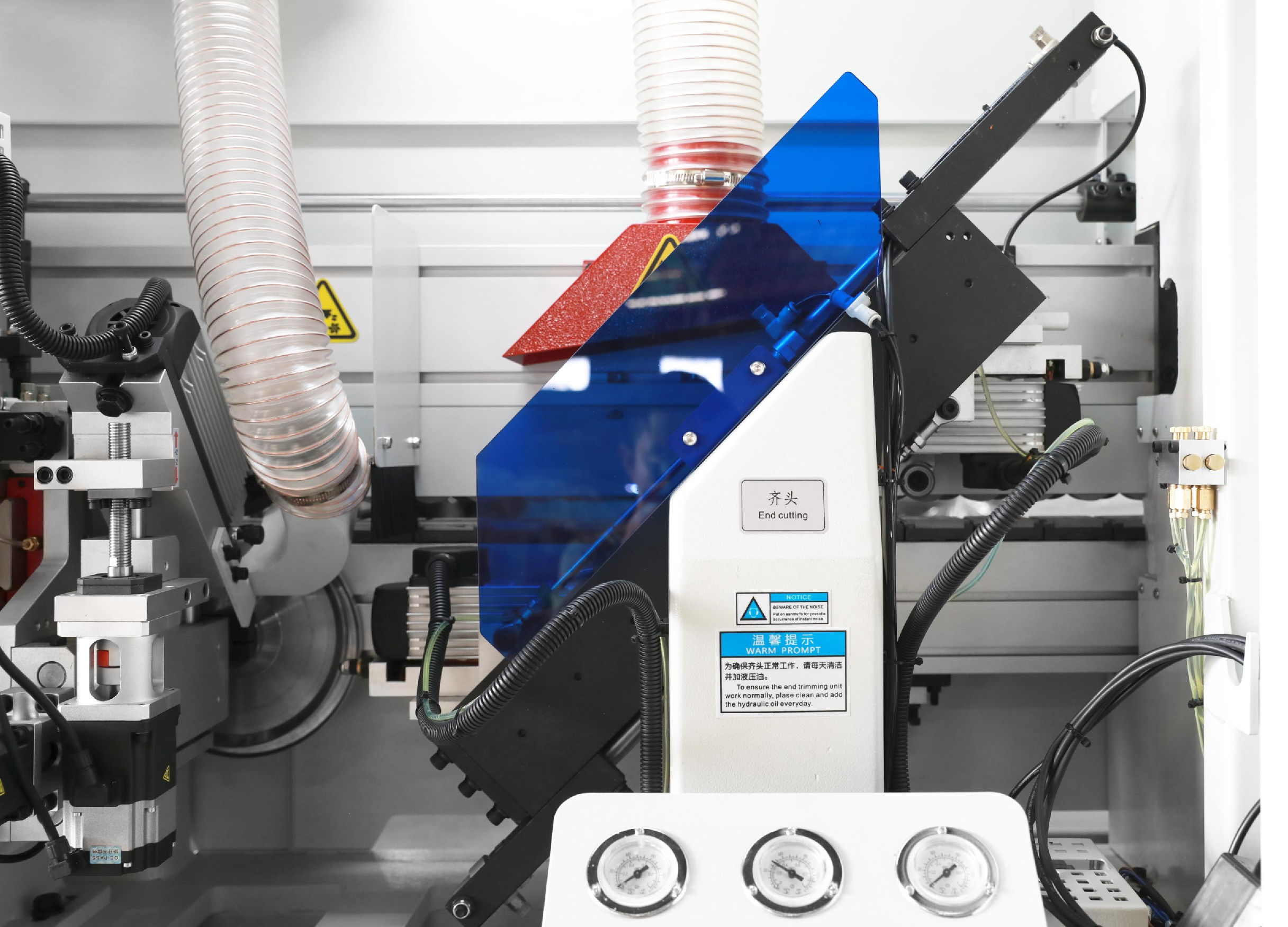

High-Tech Dual-Disc Monitoring System

The dual-disc automated tracking system used by the HUAHUA CNC HH-406RP consists of both big and tiny discs. High-frequency and high-speed motor performance are made possible by this creative design, which guarantees that our edge banding procedure stays constant. Together, these characteristics enable the machine to mill the tapes that are glued to the panel’s top and bottom sides into a clean R-shaped edge. Our reputation for high quality is strengthened by this attention to detail, which produces a product that not only looks fantastic but also endures over time.

Conclusion

By incorporating these innovative features, the HUAHUA CNC HH-406RP ensures that our edge banding process is both efficient and effective. This servo edge banding machine is a valuable addition to our operations, allowing us to achieve high-quality finishes with minimal downtime. Its focus on user convenience and operational efficiency makes it an ideal choice for anyone serious about woodworking.