At HUAHUA CNC, we understand the challenges our clients face when producing precise components for panel furniture. Using the right machinery, such as a cnc drilling machine or cnc boring machine, can significantly improve both accuracy and efficiency. Learning how to drill an angle on a cnc machine is essential for manufacturers working on cabinets, drawers, and other wooden assemblies, especially in large-scale production environments.

Importance of Proper Angle Drilling

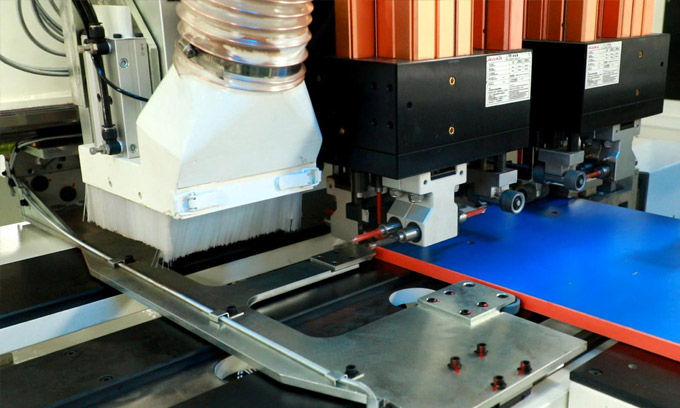

Drilling at precise angles requires careful alignment and the right equipment. Our cnc drilling machine allows simultaneous processing with two high-precision drilling heads, ensuring efficiency without compromising accuracy. This dual-head design increases production capacity by approximately 20% compared to a single-head machine, making it ideal for bathroom and kitchen cabinet production. By using the cnc boring machine, operators can create accurate angled holes consistently, even when holes are spaced more than 85mm apart, thanks to the machine’s synchronized drilling capability.

Solutions for B2B Clients and Agents

We understand that our customers, particularly local agents and distributors, need dependable machinery and support. With HUAHUA CNC, we provide free consultation for complete factory solutions, helping clients optimize layouts for maximum productivity. Our machines, including the cnc drilling machine and cnc boring machine, are manufactured with patented designs and high-quality materials. To assist agents and overseas clients, we offer full installation videos, establish professional service chat groups for immediate support, and can arrange engineers to visit sites for installation guidance and product training. Standard models typically have a delivery period of around 30 days, while customized machines or complete production lines are scheduled according to project specifics.

Advantages of Partnering with HUAHUA CNC

Our clients benefit from the combination of innovative design, precise engineering, and comprehensive service. HUAHUA CNC maintains a dedicated R&D team led by German engineers, aligning our products with European technology standards. All machines are produced in our specialized frame-processing facility, ensuring consistent quality. We hold domestic 3C certification and European CE certification, giving agents confidence in compliance and reliability. Additionally, we accept customization to suit different board sizes and furniture types, providing flexible solutions for diverse markets.

Conclusion

Mastering angled drilling on a cnc machine can greatly improve production efficiency and product quality. By choosing HUAHUA CNC, clients and agents gain access to advanced cnc drilling machine and cnc boring machine technologies, backed by extensive support, customization options, and reliable delivery schedules. Whether producing kitchen or bathroom cabinets, our solutions help partners achieve operational excellence while benefiting from professional pre-sale and after-sale services.