When we at HUAHUA CNC work with our global partners in the woodworking machinery industry, we understand that precise and efficient cutting is at the core of every production line. Knowing how to use band saw wood equipment effectively is essential for any modern furniture manufacturer that values accuracy, safety, and productivity. Our professional approach combines innovation, experience, and technology to help our clients achieve consistent cutting performance through the use of advanced wood band saw systems.

Understanding the Operation of a Wood Band Saw

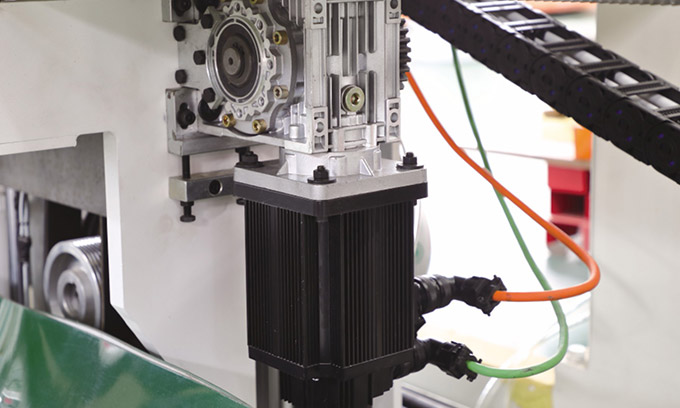

A wood band saw functions through a continuous loop blade that moves along two or more wheels, allowing it to cut through panels and solid wood with uniform precision. In industrial applications, efficiency and safety are equally critical. At HUAHUA CNC, we apply servo motor systems and optimized mechanical structures to ensure stable, vibration-free cutting performance. For example, our CNC panel saw series is equipped with a 2 kW servo motor, a saw carriage power reducer, and a gear reducer three-phase asynchronous motor—delivering high efficiency and consistent cutting accuracy during large-scale wood processing.

Why Proper Use of Band Saw Equipment Matters

Understanding how to use band saw wood machinery correctly helps maintain product quality and extend equipment life. Proper training allows operators to achieve clean, straight cuts and reduce material waste. We emphasize routine maintenance, correct blade tension, and speed adjustment according to wood density. With decades of experience, HUAHUA CNC provides customers with detailed operation manuals, installation videos, and real-time technical support to ensure the machinery performs at optimal levels.

Our Support for Global Agents and Partners

As part of our international growth strategy, we welcome cooperation with distributors and agents worldwide. We provide full technical support, competitive agent pricing, and professional after-sales assistance. Our engineering team can visit client sites for installation, commissioning, and operator training. Furthermore, our R&D department—led by experienced German engineers—ensures that each wood band saw and CNC cutting system meets European CE certification and China 3C safety standards. We also offer customized machine designs to meet local wood panel sizes and market demands, along with free factory layout consultations that optimize productivity.

Conclusion

At HUAHUA CNC, we are committed to delivering reliable, high-performance woodworking machinery that supports efficient production and long-term business growth. Learning how to use band saw wood systems properly not only enhances daily operations but also contributes to a safer, more sustainable manufacturing process. By combining advanced mechanical engineering with attentive customer service, we continue to build lasting partnerships that bring mutual success to the global woodworking industry.