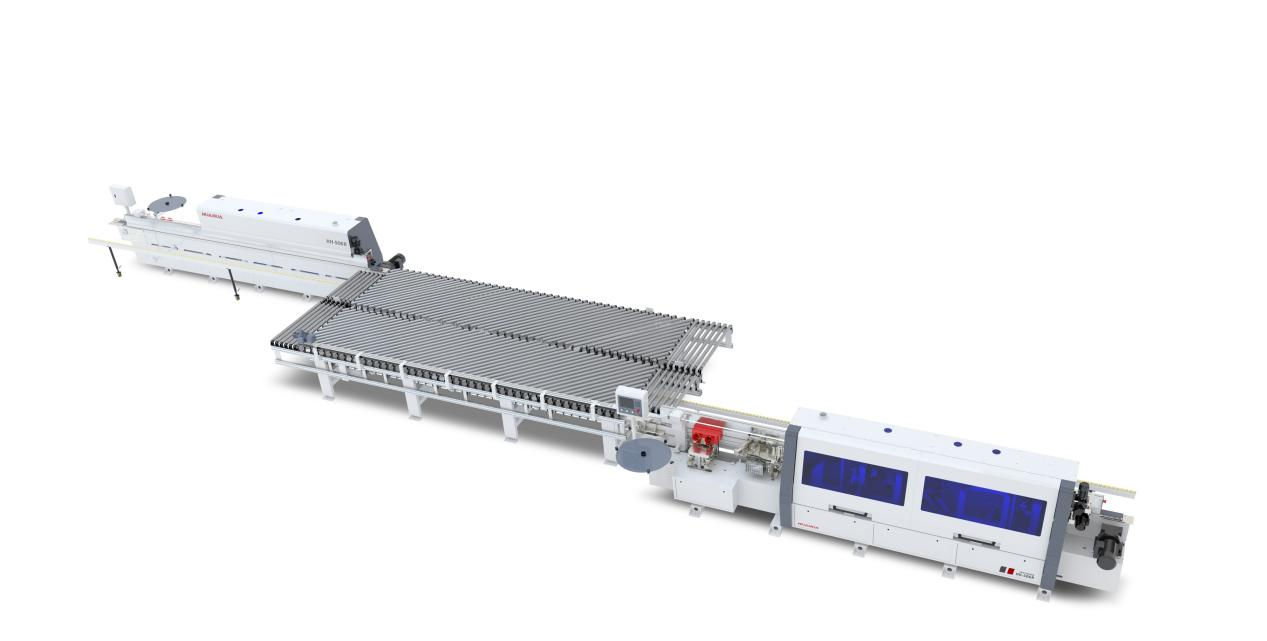

In the rapidly evolving landscape of furniture manufacturing, efficiency and precision are paramount. At HUAHUA CNC, we take the lead with our innovative Edge Banding Machine Line, offering customized panel furniture smart production solutions. This advanced system not only enhances productivity but also ensures that you are equipped to meet the demands of modern consumers in the furniture production line.

Customized Production Solutions

We are more than just a machine manufacturer; we specialize in providing cost-effective solutions tailored to your specific needs. Whether you are looking to upgrade your existing furniture production line or planning an entirely new factory layout, we have the expertise to help you succeed. Our HUAHUA CNC Edge Banding Machine Line represents a significant step toward embracing the era of Industry 4.0, integrating smart technology into every phase of production.

Innovative Features for Enhanced Efficiency

One of the standout features of our Edge Banding Machine Line is its smart touch screen operation. This user-friendly interface allows you and your operators to control the system easily, ensuring a smooth and efficient workflow. Our humanized operating system design reduces the learning curve for new users and minimizes operational errors, making it ideal for any furniture production line.

Additionally, our machine features double row left and right rollers that facilitate quick panel transfer. As the panel exits the first edge banding machine, the inclined roller connection rapidly sends it to the second machine for further processing. This seamless transfer not only speeds up production but also enhances the overall quality of the finished product, ensuring that every piece meets high standards.

Precision and Consistency

The automatic side aligner is another innovative component of our Edge Banding Machine Line. This feature uses inclined roller transfer to ensure that the panel is closely aligned with the edge, thereby improving accuracy during edge banding. The addition of a soft edge assist means that the panel is conveyed more smoothly through the system, reducing the risk of damage and ensuring a flawless finish.

Moreover, our auxiliary feeder plays a crucial role in maintaining consistency within your furniture production line. By preventing any movement during feeding, it ensures that both left and right edge banding processes adhere to the same standards. This attention to detail is critical for you to maintain high-quality output in a competitive market.

Conclusion

In conclusion, our HUAHUA CNC Edge Banding Machine Line offers a comprehensive solution for manufacturers seeking to enhance their panel furniture production capabilities. With customized production solutions, innovative features, and a focus on precision and consistency, we position your business for success in the era of Industry 4.0. Embrace the future of furniture manufacturing with HUAHUA CNC and watch your production efficiency soar.