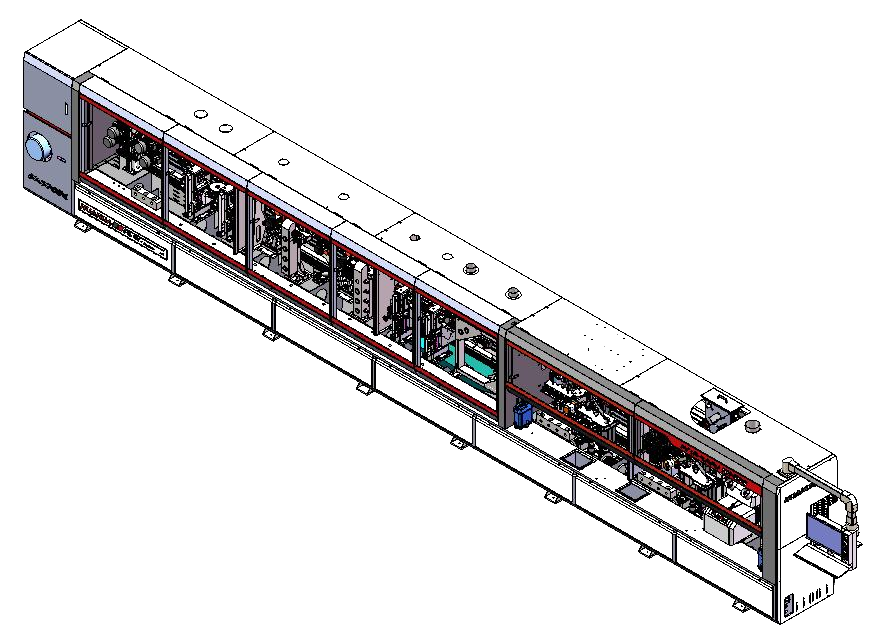

HH-796RK-SERVO

HH-796RK-SERVO

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

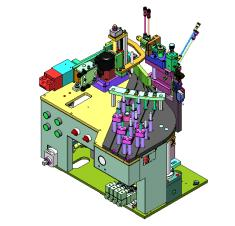

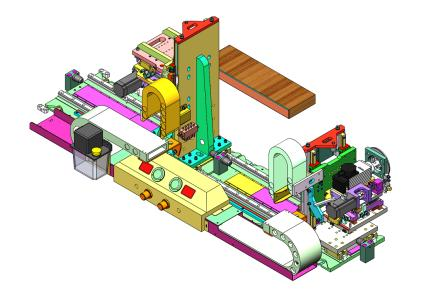

Functions

Features

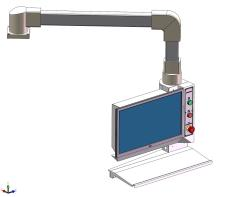

Computer

Large computer screen, clearer interface, easy to

operate.

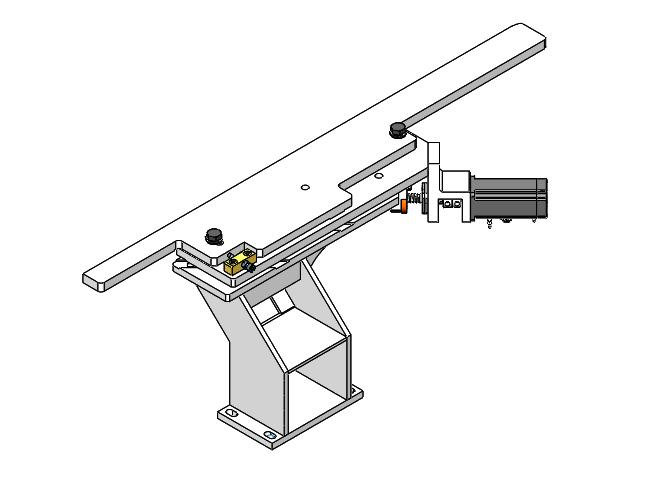

Guide plate

Servo adjustment guide plate.

Pre-milling

3.7KW motor, linear bearing model.

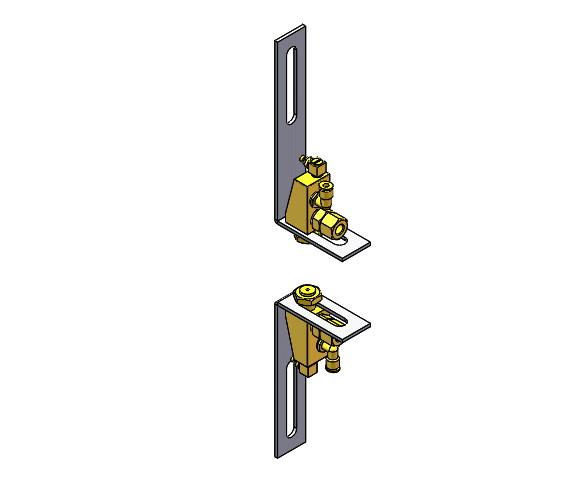

Front releasing

Spray releasing agent on the panel surface, make

panel isolated from other debris.

Heating lamp

Preheat panel edge to prevent it from cracking due to the big temperature difference.

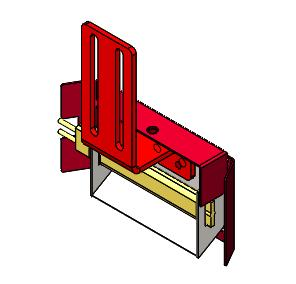

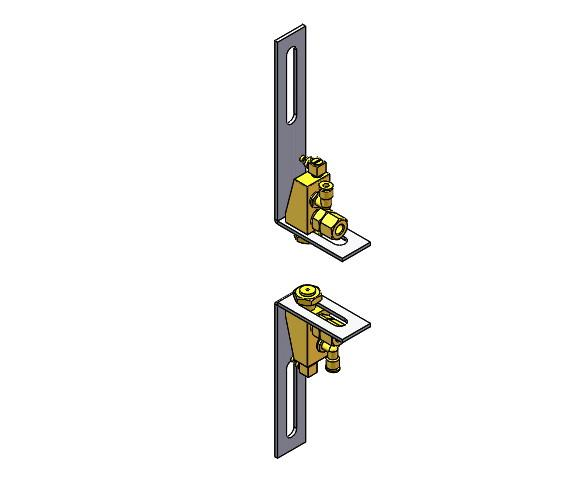

Glue

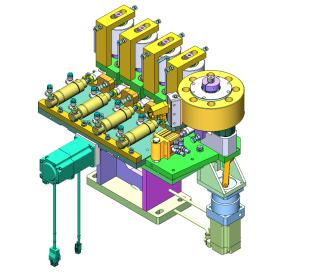

Four-channel (servo) tape feeder + no-clean glue pot +2kg PUR glue machine.

Servo adjustment for edge band pressing height and tape feeding.

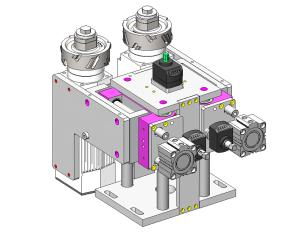

Servo yaw pressing

Servo adjustment for pressing belt and large pressing wheel.

High speed horizontal end cutting

The angle of the band cutting saw blade can be

servo-adjusted.

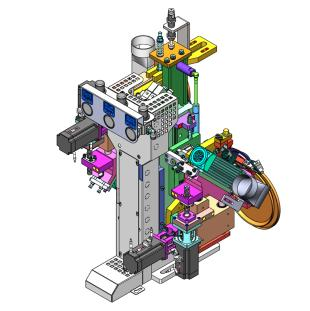

Rough trimming

Adopt large and small discs automatic tracking ,high frequency and high speed motor structure.

Trim the tapes bonded on the upper and lower sides of panel.

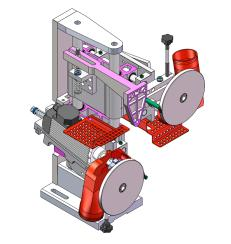

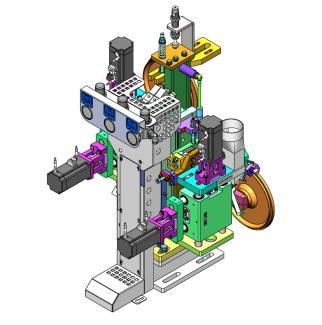

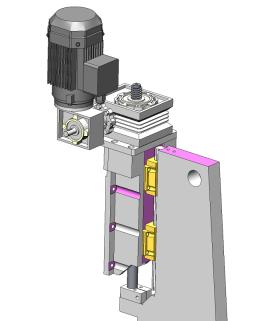

Servo multi blade fine trimming

It adopts 400W fine trimming motor, HSK25 locking knife shaft, and dual servo to achieve free switch of three arcs of R1/R1.5/R2.

Magnetic levitation corner rounding

Double-head magnetic levitation model, tracking

maximum thickness 45mm.

Servo multiblade scraping

Dual servos achieve free switch of three arcs:

R1/R1.5/R2.

Floating flat scraping

Pneumatic scraping

Remove the remaining glue extruded from the joints of the upper and lower planes of the edge banding attached to the panel.

Make it less likely to stick to the buffing wheel and reduce the frequency of polishing wheel replacement.

Off-cut

Cutting chips ensure the residual edge chips will not enter the buffing motor and conveyor motor , to improve the service life of the motors.

Rear cleaning

Spray cleaning agent on the panel surface, make

cleaning easier.

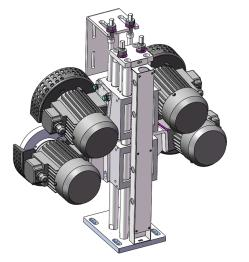

Double buffing

Adopting independent beam and column base support structure.

Stable base and operation is more stable.

Edge sealing end surface can be smoother and more beautiful.

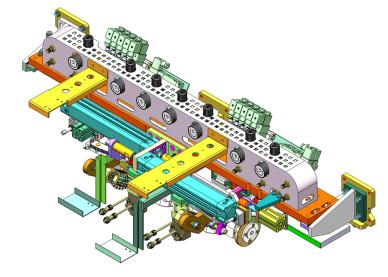

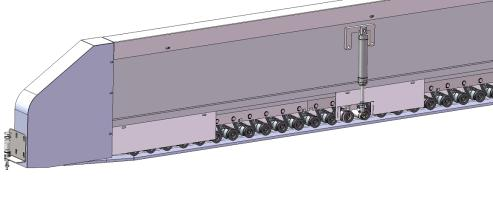

Track pressure beam

Heightened track pressure beam.

Guide rail

Integrated steel rail.

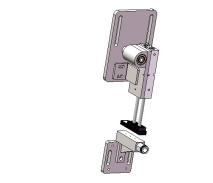

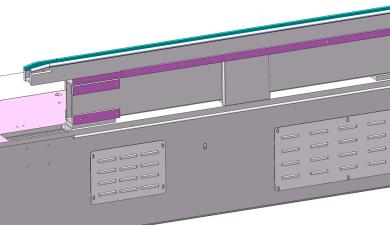

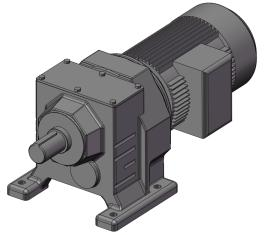

Independent lifting device

Worm Gear Reducer.

Conveying Motor

7.5kw high power motor,ensure panel stability

when transported to each processing unit.

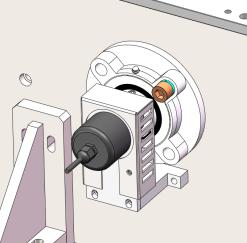

Conveyor beam

Conveyor beam encoder control.

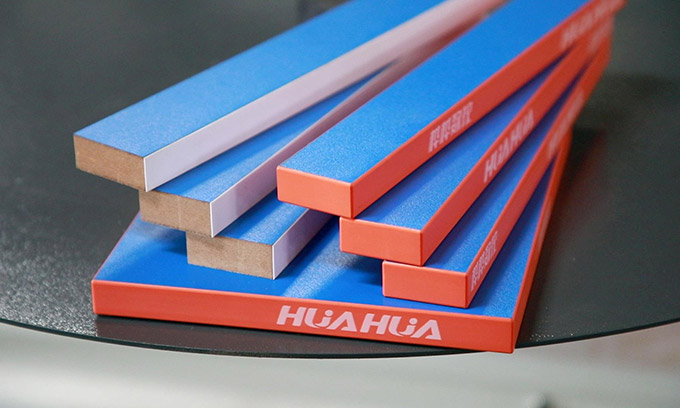

Fluency bar

Improve processing efficiency.

Technical Specifications

| Conveying speed | 22-26-28m/min |

| Panel width | ≥120mm |

| Tape width | 13-63mm |

| Working pressure | 0.65Mpa |

| Panel thickness | Corner rounding off:10-60mm

Corner rounding on :≤45mm |

| Panel length | ≥120mm |

| Tape thickness | 0.4-3.0mm |

| Machine size | 9.55*1.1*2m |

| Tape feeding (2sets) | 1.25*0.32*0.95m * 2 |

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.