SKG-812Z

SKG-812Z

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

Control system

Taiwan Syntec control system

User-friendly interface, easy operation and fast response.

After-sales service points all over the world

High performance ATC spindle router

Powerful 12KW automatic tool change

Spindle, 24000rpm, Powerful twisting force and

fast processing, is suitable for heavy cutting, milling etc.,

will keep the surface of work pieces very smooth

Round Type Tool Magazine

The round type tool magazine can hold 12 tools, and base on the principle of proximity to change tools. It is more efficient to milling.

Taiwan Syntec servo motor&driver and imported reducer

Professionally made, ensure the machine

running accurately in safe with very good

resolution and accuracy.

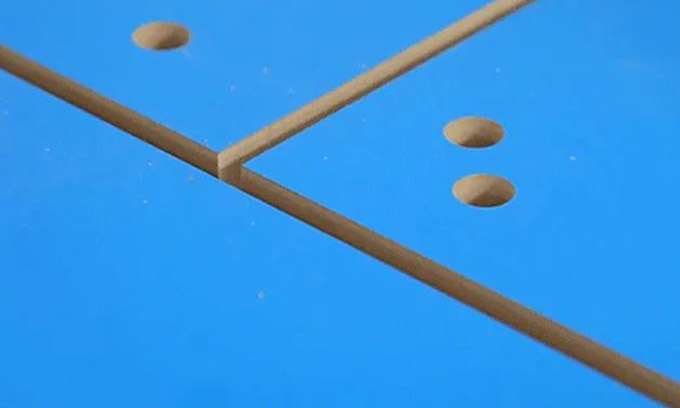

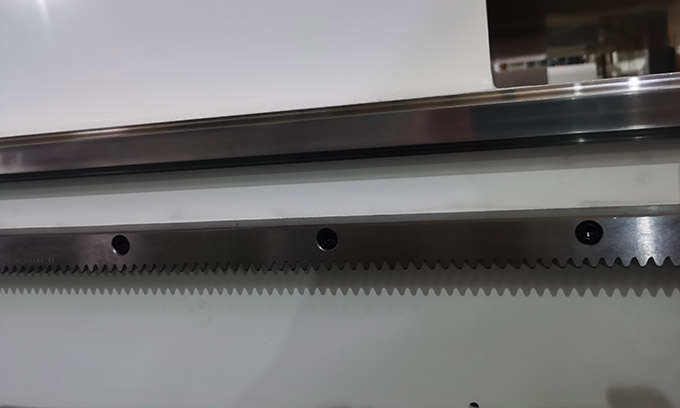

Imported linear guide rail and rack

Precision ground 30 mm imported linear

guide rails attached to the gantry, with centralized

lubrication system to the bearing blocks to

guarantee smooth travel of the spindle motor assembly.

Automatic tool sensor

The sensor will help measure the Z axis height distance

Labeling

Complete the labeling and cutting process through the pass-through more, and the labeling and cutting are uninterrupted.

Auto push device

Auto push device to help push the finished board

Auto loading device suction cup

Auto loading device suction cup pick up the board automatical from lif table

Very efficient to replace workers to go to work, saving labor costs and costs

Automatic lift table

Automatic lift table can load board,maxi loading weight is 3000kg.

Automatic conveyor belt

Automatic conveyor belt for transporting the finished board

Automatic stop and work

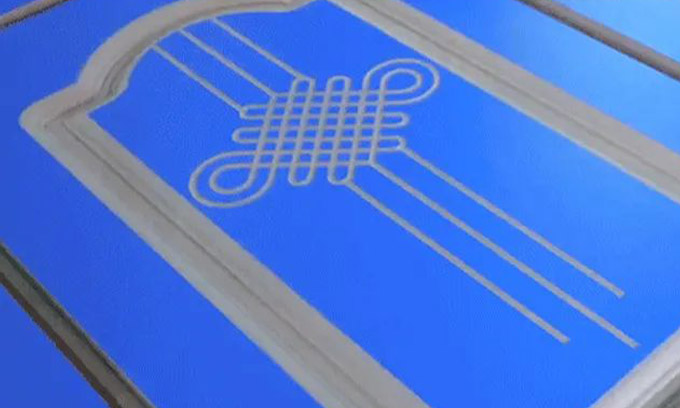

Cabinet Nesting Software

1.Self-developing nesting software. Order tracking, packaging systems and other important production links are connected in a software system.

2.Design→Optimize→Create panel list→creat labels→creat quotation of cabinet→Hardware list→creat CNC file( drilling&cutting→Output to process

Technical Specifications

| Model | SKG-812Z |

| Working Area | 1300*2800mm |

| Vacuum area | 7 areas |

| Max. Moving Speed of X axis | 80m/min |

| Max. Moving Speed of Y axis | 80m/min |

| Max. Moving Speed of Z axis | 20m/min |

| Spindle quantity | 1 |

| Spindle power | 12kw |

| Drilling Unit | option |

| Vacuum power | 7.5KW |

| Vacuum power air volume | 250m³/h |

| Total power | 24.25kw |

| Machine size | 9500*3390*2954mm |

| Gross weight | 3800kg |

Applications

What is the difference between the different structures of nesting machine?

1.Standard:Automatic pre-labeling,infeed,nesting,outfeed in one cycle to enhance productivity while reducing error

2.Autoloading and unloading with pre-labeling:Greatly helps reduce down time while improving productivity

3.Auto loading and unloading:Loading and unloading on one zone without interrupting the work cycle