The 56th China (Shanghai) International Furniture Fair (CIFF) will open its doors from September 9–12, 2025, in the National Exhibition and Convention Center (Shanghai Hongqiao). Among the highlights this year is Huahua’s showcase at Booth 8.1D05, where the company will present its latest intelligent woodworking machinery solutions in a 48 m2 exhibition space.

Known for its innovation in panel furniture production equipment, Huahua aims to demonstrate how precision, efficiency, and automation can redefine modern furniture manufacturing.

Huahua’s Highlighted Solutions at CIFF 2025

In 56th CIFF, Huahua is going to bring two of its most advanced solutions to the fair, each designed to address the challenges of panel furniture processing with higher accuracy, efficiency, and versatility.

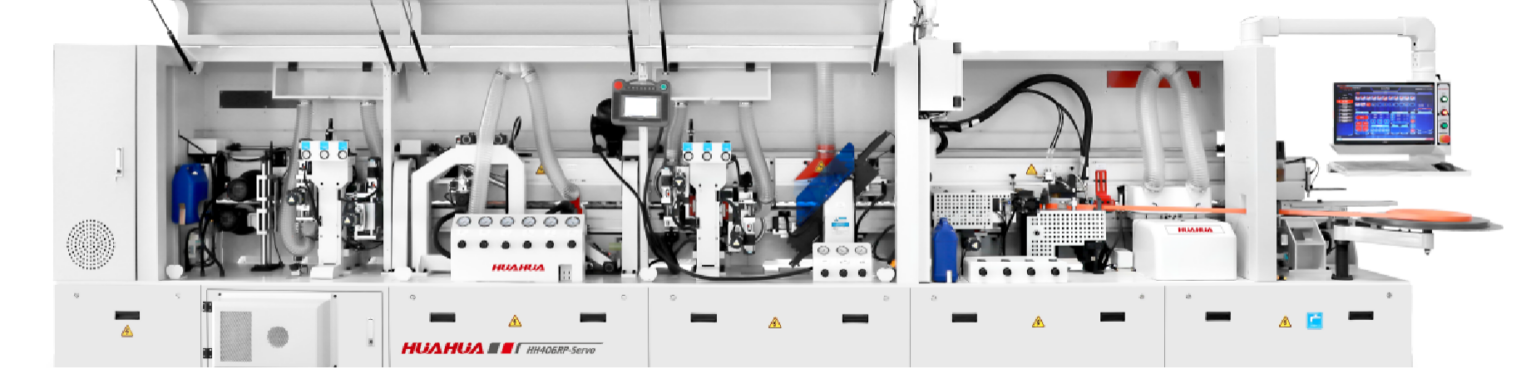

1. Servo Edge-Banding Machine: HH-406RP

Edge banding is critical to both the functionality and aesthetics of furniture. Huahua’s HH-406RP is designed to deliver high precision, smoother finishes, and consistent performance.

- Exact Panel Positioning

Huahua’s HH-406RP edge banding machine features a servo-driven positioning plate that accurately positions panels with pinpoint accuracy. Unlike traditional mechanical systems, which may drift over time, servo control ensures repeatability even in long production runs. This minimizes gaps, misalignments, and other edge defects that often frustrate manufacturers.

- Reliable Tape Bonding

To achieve seamless adhesion, the HH-406RP employs four enlarged pressing wheels along with a rubber wheel. The large diameter of the wheels applies steady and uniform pressure across the panel’s edge, while the rubber component ensures coverage of minor surface variations. The result is a consistently strong bond that withstands wear and tear.

- Smooth, Rounded Trimming

Instead of leaving sharp or uneven corners, the trimming system automatically adjusts between large and small discs while operating at high speed. This allows edges to be shaped into a gentle radius, giving furniture a softer and more refined finish. For designers, this means greater freedom in producing stylish, high-quality surfaces without the need for additional manual polishing.

- Flawless Final Surface

The final scraping step removes micro tool marks often left behind during cutting. These marks, though small, can affect both the look and feel of furniture. By eliminating them, the HH-406RP ensures that every panel leaving the line has a showroom-ready finish.

- What This Edge Banding Machine Means for Furniture Manufacturers?

The HH-406RP reduces errors, enhances edge finish quality, and improves production efficiency, perfect for companies prioritizing both durability and fine craftsmanship in furniture production. At the 56th CIFF, we welcome you to experience the performance and learn more details about HH-406RP.

2. Six-Side CNC Drilling Machine with ATC Tool Magazine: SKH-612NST

If edge banding defines a panel’s appearance, six-sided drilling defines its structure. Every modern cabinet, shelf, or modular furniture piece depends on precise drilling to ensure stability and functionality. In the 56th CIFF, Huahua’s SKH-612NST six-side CNC drilling machine with ATC addresses this need with a solution that balances speed, versatility, and high accuracy.

- Uninterrupted Tool Changes

With four independent tool magazines, the SKH-612NST is able to automatically swap between bits without halting operations. This allows one machine to handle a wide range of tasks—from drilling holes for concealed hinges to routing slots for invisible joints—in a single continuous workflow. Manufacturers who once relied on multiple machines or manual interventions will find this feature particularly valuable.

- Dual-Head Efficiency

The machine is equipped with two drilling heads that can operate simultaneously when hole spacing permits. This innovation boosts production efficiency by as much as 20% compared with traditional single-head models. For workshops producing bathroom or kitchen cabinets—where high volume and repetitive drilling patterns are common—this difference can significantly reduce lead times.

- Operator-Friendly System

While advanced in its mechanics, the SKH-612NST doesn’t overwhelm operators with complexity. Its visual interface displays data in a clear, straightforward manner, making it easy to input parameters, switch formats, and monitor performance. This lowers the learning curve for new users while allowing experienced operators to maximize productivity.

- Micron-Level Accuracy

Precision is where this machine truly shines. Its multi-point positioning technology keeps drilling deviations within a margin of just 10 wires (0.1 mm). This level of accuracy ensures that all six sides of a panel align perfectly, preventing errors that can compromise the assembly of finished furniture.

- What Does This CNC Milling Machine Means for Manufacturers?

The SKH-612NST enhances efficiency in large-scale production, reduces downtime, and ensures consistently accurate results across all six sides of a panel—helping businesses scale faster without compromising precision. If you have advanced CNC woodworking milling demand, you can’t miss visiting our booth at the 56th CIFF, 8.1D05!

Why Should You Visit Huahua at CIFF 2025?

Huahua’s exhibition at the 56th CIFF is a showcase of high-end technology from the past. Moreover, it’s a live demonstration of how next-generation woodworking machinery can transform the way panel furniture is manufactured. Except for two machines above, visitors can expect:

- First-hand demonstrations of nine high-precision edge banding machines, CNC drilling machines, and CNC wood router machines

- Insights into how automation boosts efficiency and reduces labor intensity.

- Opportunities to consult with Huahua’s technical experts on customized solutions.

Conclusion

At the 56th CIFF 2025, Huahua is set to make a strong impression by presenting cutting-edge solutions tailored to the evolving needs of the furniture industry. Whether you’re a large-scale manufacturer or a specialized workshop, Huahua’s HH-406RP and SKH-612NST offer innovative ways to achieve higher precision, productivity, and design flexibility.

Mark your calendar for September 9–12th, 2025, and visit Huahua at Booth 8.1D05 to experience the future of furniture manufacturing technology. You can also contact us today to get more information about our tour at the 56th CIFF!