At HUAHUA CNC, we continuously strive to integrate cutting-edge technologies into our machinery to help global manufacturers achieve greater efficiency and stability. Our SKH-612NS is a prime example of this commitment, combining advanced control and servo systems for superior performance. Designed as a reliable CNC six sided drilling machine, it eliminates unnecessary downtime, improves positioning accuracy, and ensures consistent results for large-scale cabinet production.

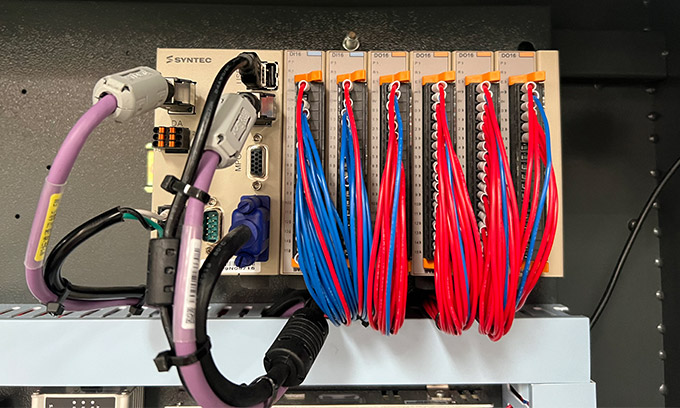

Taiwan Syntec Control System for Immediate Operation

The SKH-612NS is equipped with the Taiwan Syntec Control System, offering absolute value control. This design means there is no need for homing—the machine can be used immediately once powered on. It offers dependability even when it is being used for extended periods of time on a consistent basis because it is both stable and produces great performance. Furthermore, Syntec’s international network of after-sales service locations enables businesses all over the world to have direct access to technical support, which reduces the number of disruptions and increases the overall value of their equipment.

Precision with Taiwan Syntec Servo Motor

Another advantage of the SKH-612NS lies in its Taiwan Syntec Servo Motor. This technology ensures clamp control without the need for homing, delivering immediate usability and reducing setup time. The servo-driven clamp can reach moving speeds up to 130m/min, enabling fast positioning and precise drilling. For manufacturers focused on large-scale cabinet production, this high-speed capability translates into reduced cycle times and improved productivity, while maintaining consistent quality standards across every workpiece.

CNC Six Sided Drilling Machine for Reliable Output

As a CNC six sided drilling machine, the SKH-612NS is engineered to meet the increasing demands of modern woodworking factories. By combining Syntec’s control and servo technology, it offers a stable, long-life solution that reduces manual intervention and ensures repeatable accuracy. Whether for bathroom cabinets, kitchen cabinets, or other customized panel furniture, the machine delivers seamless six-sided processing in one setup, helping businesses achieve reliable output with reduced operational complexity.

Conclusion

At HUAHUA CNC, we understand that manufacturers need machinery that combines precision, speed, and durability. The SKH-612NS, equipped with the Taiwan Syntec Control System and Taiwan Syntec Servo Motor, is built to deliver immediate usability, rapid processing, and global service support. As industries continue to demand higher efficiency, this solution provides the advanced control and stability required for sustainable growth in competitive markets. With its user-friendly interface, reliable performance, and reduced maintenance needs, the SKH-612NS helps manufacturers optimize production lines, cut downtime, and achieve consistent quality standards across diverse applications and international operations.