At HUAHUA CNC, we are dedicated to advancing woodworking production with high-performance solutions tailored for global manufacturers. Our SKH-612NS Precision Double Drilling Heads machine represents a leap forward in efficiency, precision, and versatility. Designed to handle six-sided machining, drilling, grooving, and milling, this machine is an essential choice for enterprises seeking scalable and reliable equipment. With simultaneous processing and advanced engineering, the SKH-612NS is particularly suited for bathroom cabinet and kitchen cabinet production.

Advanced Double Drilling Heads for Higher Productivity

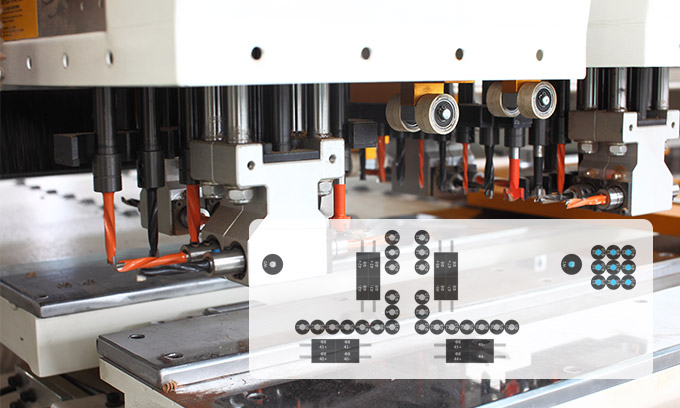

The SKH-612NS features two high-precision drilling heads, delivering performance that is 20% more efficient than a single-head machine. Equipped with carefully engineered drilling bits—Top: (Vertical 12 + Horizontal 8) × 2 groups and Bottom: Vertical 9 pcs—the machine ensures consistent accuracy even during high-volume production. When the distance between two holes exceeds 85mm, the dual drilling heads can operate simultaneously, maximizing throughput while maintaining precision. This innovation makes the SKH-612NS a dependable partner for manufacturers who demand both speed and accuracy in daily operations.

Powerful Milling Capabilities

Beyond drilling, the SKH-612NS is equipped with dual 3.5kW milling spindles (1 top and 1 bottom), allowing versatile material processing. Whether it is edge grooving or surface milling, the spindles deliver stable performance with reliable power output. The integration of drilling and milling in a single structure reduces the need for multiple setups, saving time and lowering production costs. For businesses producing bathroom or kitchen cabinets, this integrated approach significantly streamlines the workflow, offering higher consistency across all panels.

CNC Six Sided Drilling Machine for Complex Requirements

As the woodworking industry evolves, manufacturers require flexible solutions that can meet a variety of production needs. The SKH-612NS functions as a CNC six sided drilling machine, capable of handling drilling, grooving, and milling in one cycle. This comprehensive functionality minimizes repositioning errors and reduces manual intervention, ensuring high precision across complex production requirements. By combining automation with robust hardware design, the machine delivers the stability and repeatability essential for scaling up in competitive markets.

Conclusion

At HUAHUA CNC, we understand the challenges furniture manufacturers face in balancing quality, speed, and cost. The SKH-612NS Precision Double Drilling Heads machine provides a proven solution, combining dual-head efficiency with powerful milling spindles for comprehensive six-sided processing. As a CNC six sided drilling machine, it empowers businesses to achieve higher productivity, reduced downtime, and improved quality assurance. With the SKH-612NS, we are not just providing machinery—we are delivering a pathway to greater efficiency and long-term competitiveness in global cabinet production.