At HUAHUA CNC, we focus on creating solutions that enhance production efficiency, improve processing quality, and provide long-term value for manufacturers in the woodworking industry. With years of expertise in edge processing technology, we have developed the HH-796RK-SERVO, a high-performance edge banding machine designed to deliver speed, precision, and versatility. Its intelligent servo-controlled systems and advanced trimming functions make it an ideal choice for businesses seeking reliable equipment for demanding production environments.

High-Speed Horizontal End Cutting with Servo Adjustment

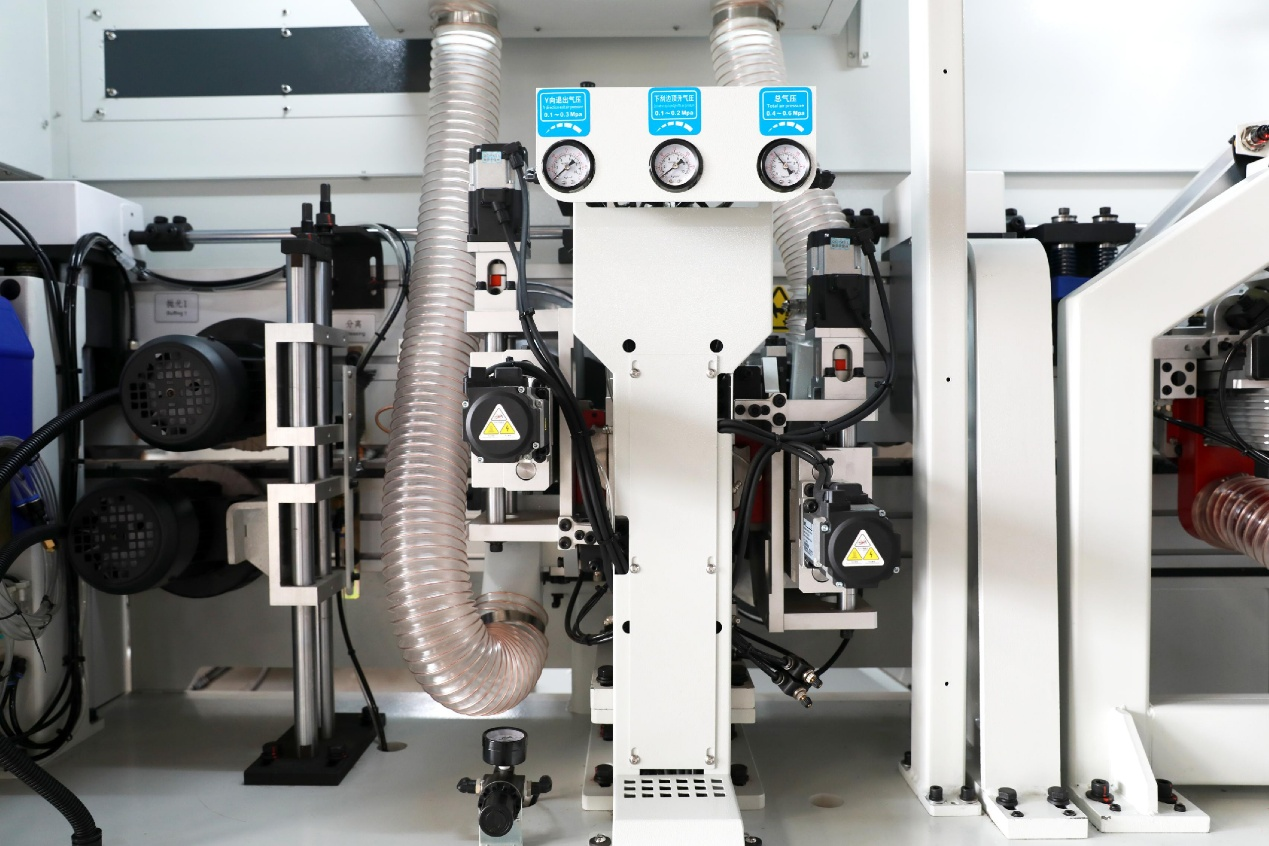

The HH-796RK-SERVO is equipped with a high-speed horizontal end cutting system that ensures clean, accurate cutting at every stage. The angle of the band cutting saw blade can be precisely adjusted using a servo system, eliminating manual adjustments and increasing overall accuracy. This automated adjustment capability not only improves production speed but also ensures consistent cutting quality across multiple workpieces. For manufacturers, this means reduced downtime, greater efficiency, and improved reliability in day-to-day operations.

Rough Trimming with Automatic Tracking

To achieve superior results, the HH-796RK-SERVO incorporates an advanced rough trimming system. By adopting large and small discs with automatic tracking, supported by a high-frequency, high-speed motor structure, the machine effectively trims the upper and lower sides of bonded tapes. This ensures that the panels maintain a smooth and uniform finish, free from excess material. The automated tracking design reduces operator involvement while improving stability and precision, making it an essential function for consistent large-scale production.

Servo Multi-Blade Fine Trimming for Versatile Results

The fine trimming capability of the HH-796RK-SERVO sets it apart as a versatile solution. It adopts a 400W fine trimming motor, an HSK25 locking knife shaft, and dual servo technology to enable quick and precise adjustments. With this system, operators can freely switch between three arcs—R1, R1.5, and R2—according to processing requirements. This flexibility ensures that manufacturers can meet a wide variety of design specifications without needing additional equipment. By combining power, accuracy, and adjustability, the fine trimming function enhances both production efficiency and product quality.

Conclusion

At HUAHUA CNC, we are dedicated to providing advanced machinery that helps our clients remain competitive in today’s woodworking industry. The HH-796RK-SERVO is a prime example of this commitment, offering high-speed end cutting, automated rough trimming, and versatile servo-controlled fine trimming in one solution. As a trusted provider of edge banding machine technology, we continue to deliver equipment that improves productivity, enhances safety, and ensures precision for long-term success.