At HUAHUA CNC, we have been focused on delivering high-quality woodworking machinery for panel furniture manufacturers. One of the essential aspects of improving production efficiency is the integration of servo motor machine technology with edge banding machine operations. By combining these two systems, we help our clients achieve consistent precision, high-speed processing, and superior finish quality throughout their production lines.

Installing a Servo Motor on a Sewing Machine

When installing a servo motor machine on a sewing or trimming unit, proper alignment with the machine’s drive system is crucial. We ensure that each motor is securely mounted, calibrated for the correct speed and torque, and tested for vibration-free operation. For our Servo Multi-radius Fine Trimming units, which trim tapes bonded on both sides of panels into R-shaped edges, the motor’s correct setup directly impacts the accuracy of trimming and the final edge quality. Our engineers provide step-by-step installation guidance, and if needed, they can travel onsite to supervise the installation, calibrate the motor, and train staff to operate the machine efficiently.

Optimizing Edge Banding Operations

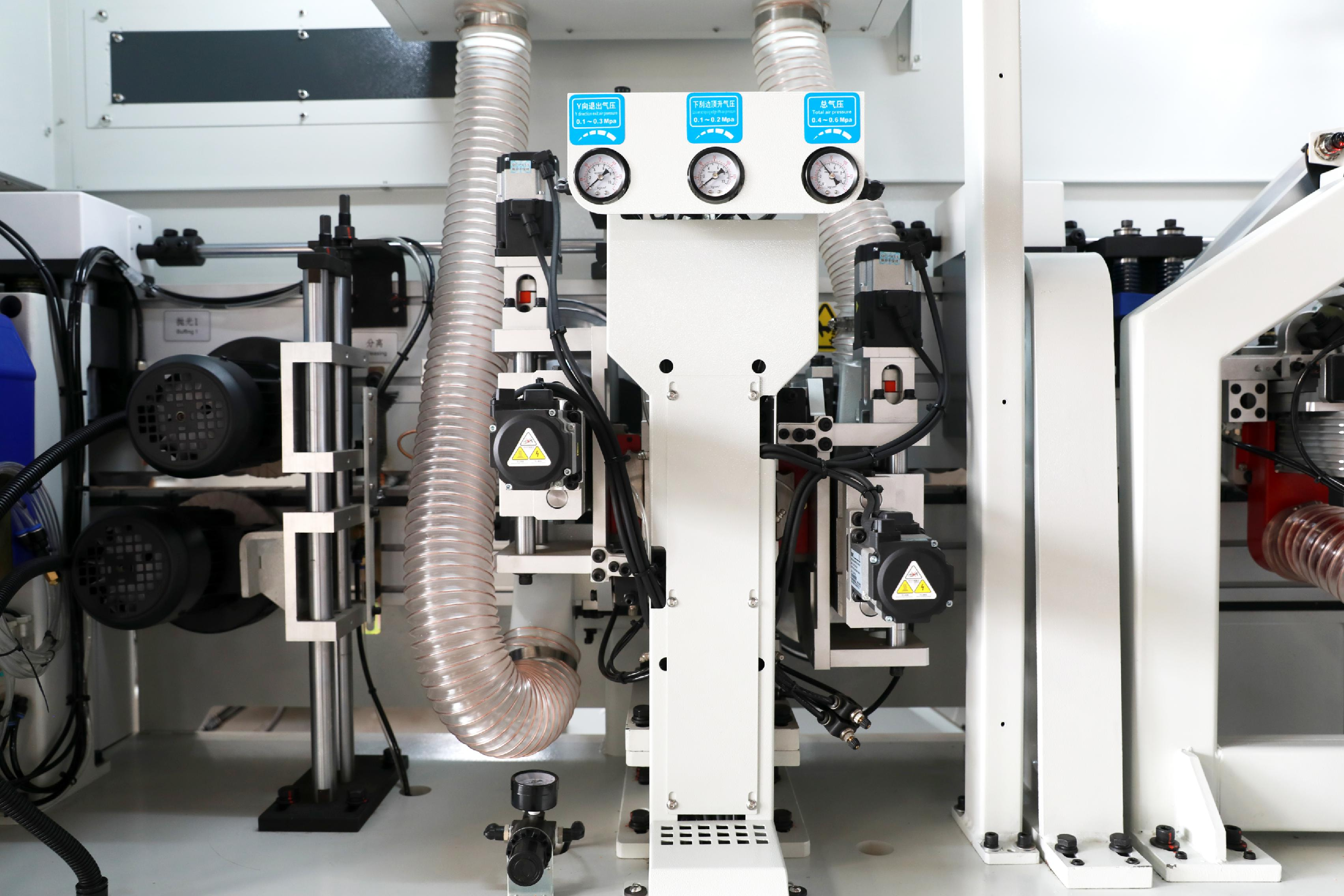

Integrating a servo motor machine with an edge banding machine enhances automation and reduces manual intervention. The HH-406RP unit utilizes large and small discs with automatic tracking to handle complex panel shapes, offering high-frequency, high-speed performance. This setup not only improves panel edge precision but also minimizes material waste and labor costs. We provide free consultations for clients planning complete factory layouts, allowing them to maximize output and optimize workflow. Agents and distributors benefit from detailed guidance on machine selection, integration, and production line design tailored to local market requirements.

Supporting Our Global Partners

We understand that overseas clients often have questions regarding service, delivery, and agency opportunities. To address these, we provide comprehensive installation videos, establish professional after-sales group chats for real-time support, and arrange engineers to visit sites for hands-on guidance. Standard machines typically have a 30-day delivery period, while customized units or full-line solutions vary depending on project scope. For potential agents, we offer competitive pricing and flexible cooperation models to ensure mutual growth. This includes ongoing training, technical support, and marketing assistance to help agents succeed in their local markets.

Conclusion

At HUAHUA CNC, our focus on integrating servo motor machine technology with advanced edge banding machine systems demonstrates our commitment to precision, efficiency, and reliability. With patented designs, strict quality control, 3C and CE certifications, and a dedicated global support network, we provide agents and clients with solutions that meet modern production demands. Through hands-on training, onsite support, and customization options, we empower our partners to maintain high-quality manufacturing standards while achieving optimal productivity. By collaborating with us, agents can expand their local market offerings with machinery that balances innovation, efficiency, and dependable service.