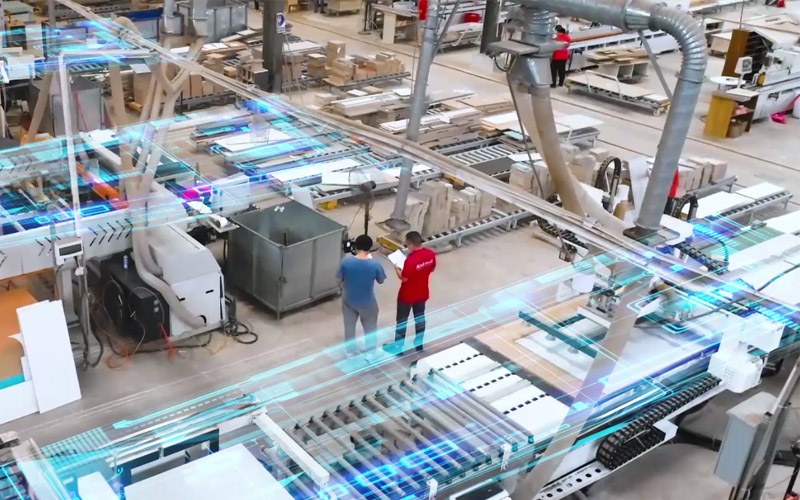

Information-based furniture production mode

Integrate “planning + informatization + equipment” to help enterprises produce efficiently and quickly

1800 m2, 90 meters long

The fastest processing speed is 26 meters per minute, and the single-day production capacity is 350-380 large boards

Precise cutting and intelligent

3 cutting machines are responsible for the optimal cutting of panels

Automatic edge banding

Automatic code scanning, high-quality edge banding

Panels shunting rotary roller line

Intelligent rotation, penal fast walking.

Penal storage bin

Temporary storage of panels to optimize efficiency.

CNC drilling and milling

3 sets of six-sided drilling machine online, fast drilling, slotting, minimum 50*250 panels can be processed.

Independent R&D of HHM software system

Independent research and development by HUAHUA CNC, easy to operate and quick to use.

Sorting area

Finished product sorting, quick classification.

Independent R&D of MES system

Real-time monitoring of the machining process.

Product storage

Clean, scan the code, pack, store… all are orderly.