HUAHUA CNC continues to innovate in the woodworking machinery industry by providing solutions that combine efficiency, accuracy, and reliability. Our cnc drilling machine and cnc boring machine are designed to streamline furniture manufacturing processes, reduce errors, and enhance production consistency. We focus on delivering practical solutions that help our partners implement optimized factory layouts while meeting international quality standards.

The Function and Benefits of a CNC Drilling Machine

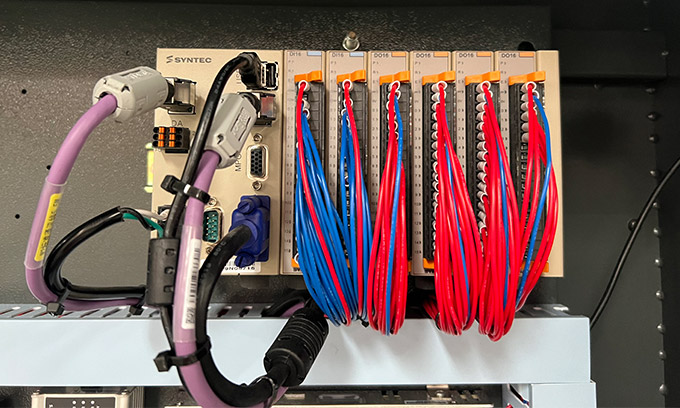

A cnc drilling machine is essential for automating the drilling of multiple holes in wooden panels, ensuring precise placement and uniformity. Equipped with the Taiwan Syntec Control System, our machines use absolute value control, meaning they can operate immediately after powering on without the need for homing. This design ensures stable performance over extended periods of continuous use. By combining advanced software and robust hardware, our cnc drilling machine guarantees consistent results whether processing single components or full production lines, which is crucial for modern furniture manufacturing.

Supporting Partners with Comprehensive Services

We provide our clients and local agents with extensive support to ensure smooth operations. Our cnc boring machine and other equipment come with professional pre-sale consultation, including tailored solutions for different board sizes and furniture types. We maintain 24-hour after-sales support through dedicated service groups, provide on-site installation guidance, and offer product training to help partners operate efficiently. Overseas clients also benefit from installation videos and Syntec’s global service network, which allows for timely troubleshooting and ongoing technical assistance.

Advantages for Agents and Business Growth

Collaboration with HUAHUA CNC allows agents to expand their local woodworking business with confidence. Common questions we receive include: “How is after-sales support handled?”—we provide videos, online service groups, and can send engineers to client sites for installation or troubleshooting. Another frequent question is “What is the delivery timeline?”—standard machines usually ship in around 30 days, while customized machines or full production lines depend on project specifics. Agents also ask about local representation; while some regions already have partners, we are actively seeking new agents globally. Working with us offers access to flexible pricing, promotional support, and innovative machinery developed by our R&D team, led by German engineers who align with advanced European technology standards.

Conclusion

A cnc drilling machine from HUAHUA CNC represents more than machinery—it is a critical tool for precise, efficient, and high-quality woodworking production. Combined with our cnc boring machine, certified quality standards, and professional support, we empower agents and partners to maximize operational efficiency and meet diverse market needs. Through advanced technology, customized solutions, and dedicated service, we ensure partners achieve optimal performance and long-term success in the furniture manufacturing industry.