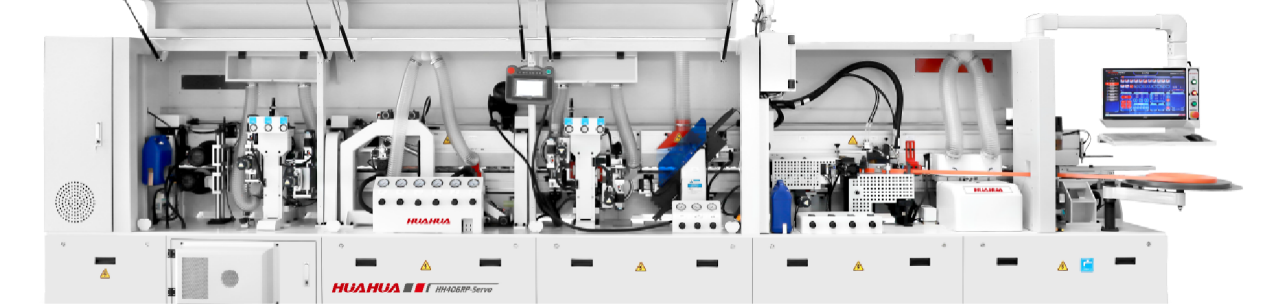

The HUAHUA CNC HH-406RP Servo Edge Banding Machine is a state-of-the-art solution tailored for precision in woodworking applications. This advanced machine is designed to meet the demands of modern woodworking with innovative features that enhance the overall quality and efficiency of edge banding processes. From its powerful motor to its effective dust collection system, the HH-406RP is a game changer in the industry.

Enhanced Pre-Milling Capabilities

One of the standout features of the HH-406RP is its impressive pre-milling functionality. This machine allows for a maximum pre-milling height of 40mm, with an optional upgrade to 65mm. By employing the pre-milling process, the HH-406RP effectively removes surface imperfections, ensuring a perfectly smooth finish before the application of edge banding. This meticulous preparation is essential for achieving high-quality results, as it allows the adhesive to bond more effectively to the material.

Additionally, the machine is equipped with a spiral dust collection system that significantly improves dust management. This feature ensures that the workspace remains clean, which not only enhances the operator’s safety but also contributes to a more efficient workflow. By reducing the amount of dust generated during the milling process, the HH-406RP minimizes downtime for cleaning and increases overall productivity.

Powerful Performance and Precision

The HH-406RP is powered by a robust 7kw high-power motor, delivering exceptional performance that meets the rigorous demands of various woodworking tasks. The milling panel surface is designed with corrugations and expanded edges, which improve the bonding process and ensure that the edge banding adheres securely and lasts longer.

Moreover, the servo pressing mechanism is a highlight of this machine. It features four strong pressing wheels and one rubber wheel, which work together to ensure a tight fit. The enlarged diameter of the pressing wheel (150mm) provides better coverage and stability during operation. This design guarantees that the edge banding is applied evenly, eliminating the risk of gaps or misalignment.

Conclusion

In summary, the HUAHUA CNC servo edge banding machine HH-406RP is an indispensable tool for professionals in the woodworking industry. Its advanced features, such as effective pre-milling, powerful motor, and precision pressing system, make it an ideal choice for achieving high-quality edge banding results. Investing in the HH-406RP means choosing reliability, efficiency, and innovation for all your woodworking projects. Not only can consumers anticipate increased production with this equipment, but they can also anticipate higher craftsmanship that is not only durable but also endures the test of time.