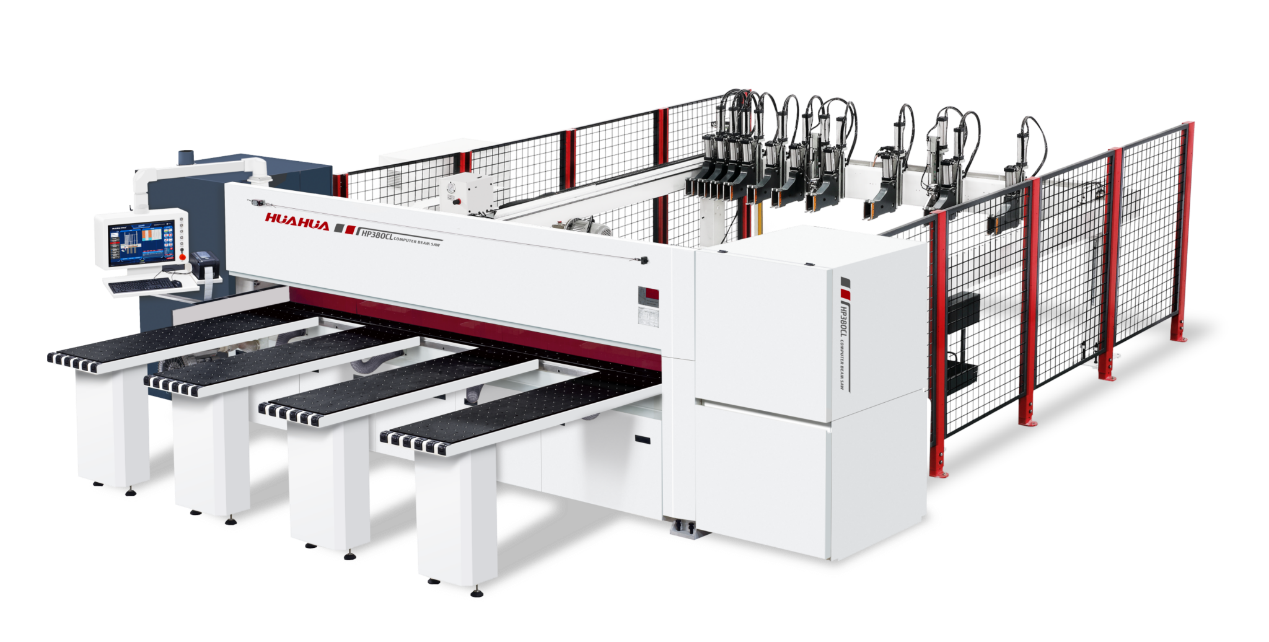

How can woodworking manufacturers achieve both high-speed production and reliable safety in one solution? At HUAHUA CNC, we are dedicated to delivering advanced woodworking machinery that helps manufacturers achieve efficiency, precision, and long-term reliability. With nearly two decades of industry expertise, we continue to design machines that improve productivity while ensuring operator safety. Our latest innovation, the HP380CL, is a high-performance CNC panel saw engineered to meet the demands of modern panel processing.

Automatic Positioning for Stability and Safety

The HP380CL features an automatic positioning system for its pressure beam, eliminating the need for manual adjustment. Both the saw blade and pressure beam automatically adjust their lifting height according to the thickness of the plate, ensuring stability throughout the cutting process. This intelligent automation not only improves accuracy but also greatly enhances equipment safety by preventing misoperation. By reducing manual involvement, manufacturers can rely on consistent performance while minimizing operator risk.

Independent Lifting for High-Speed Cutting

Efficiency is central to the design of the HP380CL. Both large and small saws can be lifted independently, with the sawing stroke automatically positioned according to board thickness. This reduces idle time and streamlines the cutting process. With a saw base speed of up to 120m/min, the machine delivers high-speed performance suitable for large-scale production environments. Manufacturers benefit from shorter processing cycles, improved throughput, and reliable accuracy—key factors for staying competitive in today’s woodworking industry.

Upgraded Countertop Design for Durability

The HP380CL also incorporates an upgraded countertop design to optimize durability and quality. The narrower table helps effectively prevent edge bursting during cutting, ensuring cleaner finishes on all panels. Its 25mm thickened table provides strength and stability, resisting deformation even under long-term use. To further protect materials, the 1.8m × 3m air-floating table, assisted by rollers, allows panels to glide smoothly without surface damage. This design not only extends the machine’s life but also safeguards the quality of every workpiece.

Conclusion

At HUAHUA CNC, we combine innovation, safety, and efficiency to deliver solutions that support our clients’ growth. The HP380CL embodies these values with its automatic positioning, independent saw lifting, and reinforced countertop design. As a trusted CNC panel saw provider, we are committed to offering equipment that reduces manual adjustments, improves processing speed, and ensures reliable durability. Choosing HUAHUA CNC means choosing advanced technology that empowers businesses to achieve higher efficiency and long-term success.