Modern furniture manufacturing is made more accurate, automated, and efficient by the woodworking equipment we design at HUAHUA CNC. Our HH-406RP auto edge bander is a prime example of this commitment. Engineered with powerful motors, intelligent tracking systems, and advanced trimming features, this machine ensures flawless edge finishing with minimal manual effort. Whether you’re producing cabinets, wardrobes, or custom panel furniture, the HH-406RP delivers professional results that meet the highest standards.

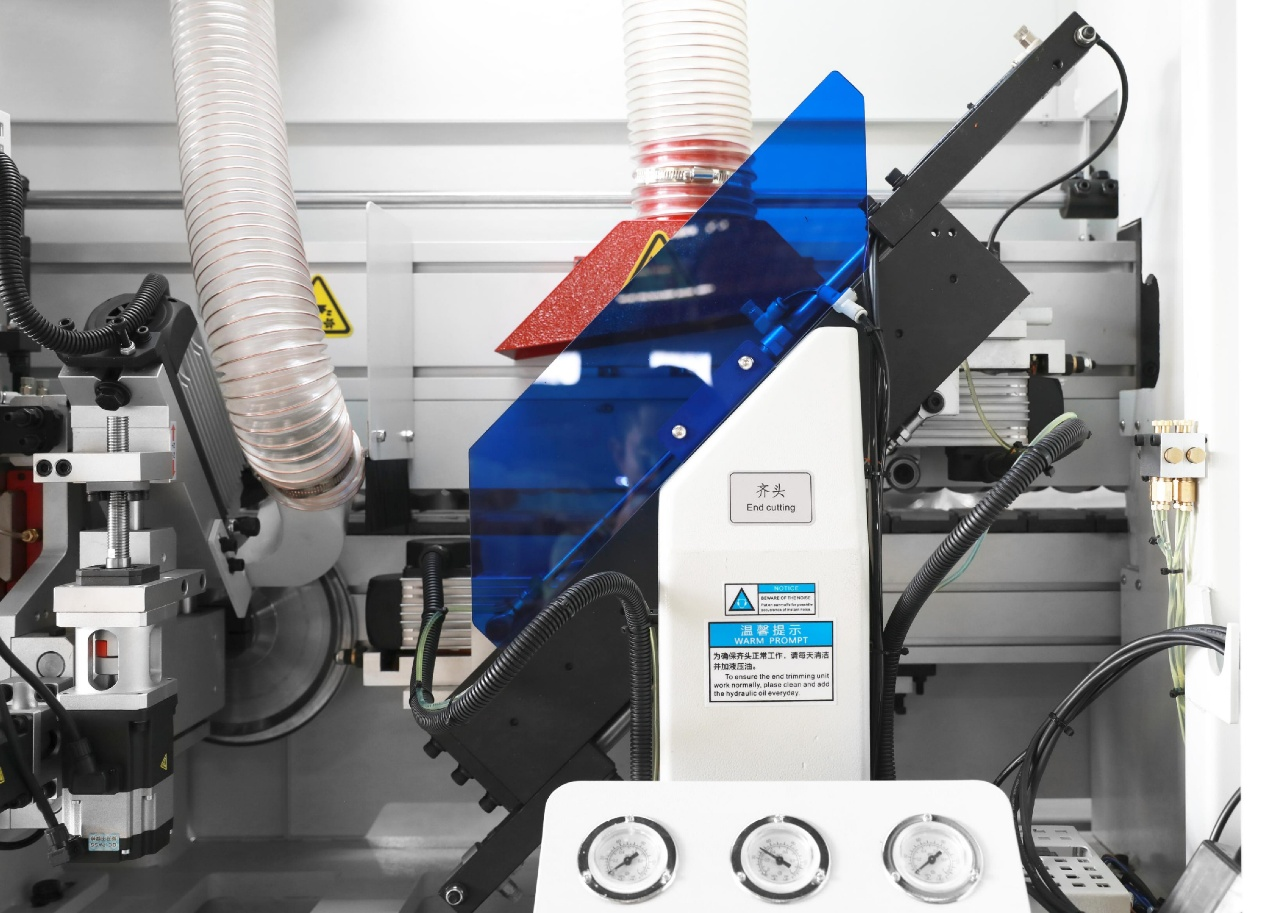

High-Speed End Cutting for Clean Alignment

End cutting is the first critical step in edge banding, and the HH-406RP excels with a dual 0.37kW motor configuration. It adopts an automatic template tracking system paired with high-frequency, high-speed motor operation. This setup rapidly trims the excess tape at the front and rear edges of the panel, ensuring both ends align perfectly with the panel’s surface. The result is a smooth and clean finish with no overhangs, which improves both appearance and structural quality. For manufacturers focused on delivering seamless panel furniture, this is an essential feature.

Dual Positioning Corner Rounding for Precise Shaping

Edge tape corners require extra attention to achieve a rounded, professional look. The HH-406RP auto edge bander is equipped with a powerful 3kW*4 dual positioning corner rounding system. This feature mills the four corners of the tape into smooth R arc shapes, eliminating sharp edges and enhancing overall product safety and aesthetics.

By precisely shaping each corner with automatic positioning and stable motor control, our system ensures consistent finishing across all panel types. Whether working with thin boards or thicker materials, this function helps create a high-end appearance that today’s customers expect.

Servo Multi-Radius Fine Trimming for Flawless Edges

For perfect upper and lower tape trimming, the HH-406RP integrates a servo-controlled multi-radius fine trimming system. This advanced mechanism uses a combination of large and small discs with automatic tracking and high-frequency motors to trim the bonded edge tape into a clean R-shape.

This system eliminates rough cuts and uneven finishes, ensuring the upper and lower sides of the panel are refined and smooth. It also adapts well to various edge thicknesses and materials, giving manufacturers the flexibility needed for custom production. This level of detail is what makes the HH-406RP a truly versatile and high-performance auto edge bander.

Conclusion

At HUAHUA CNC, we continuously strive to provide innovative edge banding solutions that elevate both productivity and product quality. The HH-406RP auto edge bander combines high-speed cutting, precise corner rounding, and intelligent fine trimming to deliver perfect edge finishing with minimal manual intervention. If you’re ready to streamline your edge banding process and deliver showroom-quality results, the HH-406RP is your next step forward. Choose HUAHUA CNC to power your panel furniture production with precision and performance.