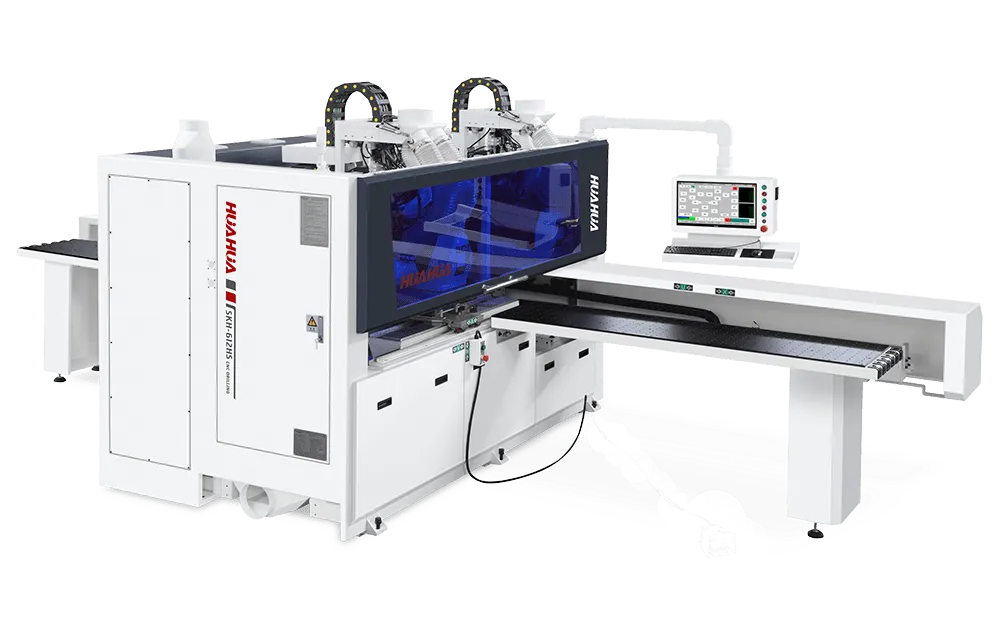

In the modern woodworking industry, automation is no longer a luxury; it’s a necessity. At HUAHUA CNC, we recognize the importance of reducing manual labor while improving safety and efficiency. Our CNC wood drilling machine is designed to automate every aspect of the woodworking process, from feeding and aligning to drilling, grooving, and unloading.

Automatic Feeding System for Enhanced Safety

One of the standout features of our machines is the automatic feeding system. This technology allows materials to be loaded into the machine without the need for manual intervention, significantly reducing the risk of injury and enhancing workflow efficiency. By automating the feeding process, operators can focus on other critical tasks, leading to a more productive work environment. This not only improves safety but also accelerates the overall production timeline.

Precision Alignment for Quality Assurance

In addition to feeding, our CNC wood drilling machine automates the alignment process as well. Accurate alignment is crucial for achieving high-quality results, and our technology ensures that each piece is perfectly positioned before drilling begins. This level of precision minimizes errors and maximizes the quality of the finished product, ensuring that you meet customer expectations consistently.

Affordable Options for Woodworking Companies

Businesses that specialize in furniture, cabinets, and other intricate wood goods would especially benefit from this six-sided drilling capacity. You may enhance productivity and save labor expenses by doing away with the requirement for several runs. This effectiveness improves the overall quality of your final products in addition to saving time. The chance of misalignment is greatly reduced when all sides are precisely drilled in a single operation, guaranteeing that your goods live up to client expectations.

Streamlined Drilling and Grooving Operations

The drilling and grooving processes are also fully automated, allowing for consistent and efficient operation. With HUAHUA CNC’s technology, you no longer have to worry about the time-consuming manual processes that can slow down production. Instead, our machines handle everything seamlessly, allowing you to focus on scaling your business and expanding your offerings.

Efficient Unloading Process for Continuous Workflow

Finally, the unloading process is automated as well, ensuring that finished products are efficiently removed from the machine without interrupting the workflow. This comprehensive approach to automation not only enhances productivity but also improves safety in the workplace. By streamlining every step of the process, you can ensure that your operations run smoothly and efficiently.

Conclusion

In conclusion, investing in HUAHUA CNC‘s CNC wood drilling machine means embracing the future of woodworking. Our commitment to automating every process will help you reduce heavy manual labor, improve safety, and enhance overall efficiency. Contact us today to discover how our innovative solutions can transform your woodworking operations, elevate your productivity, and ensure your business remains competitive in an ever-evolving market.