In our pursuit of providing efficient and precise woodworking equipment, we at HUAHUA CNC have continuously improved the design and functionality of our machines. A key focus of our production line is the cnc drilling machine, which plays a critical role in modern panel furniture manufacturing. By integrating advanced engineering principles and industry insights, we ensure that our cnc drilling machine meets the high standards expected by our partners and agents worldwide.

Understanding How a CNC Drilling Machine Works

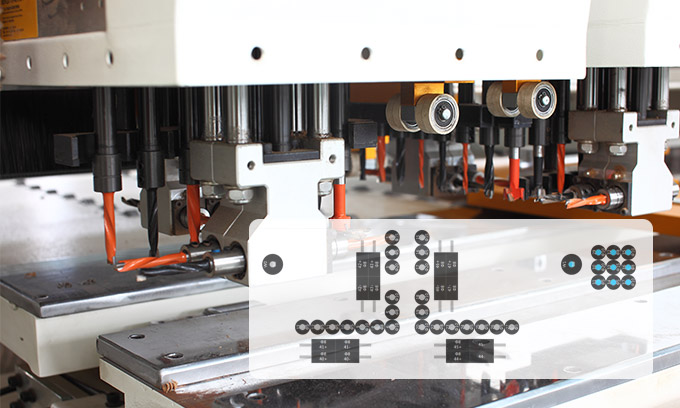

A cnc drilling machine operates through computer numerical control, allowing precise movements across multiple axes. Our machines are equipped with precision double drilling heads, capable of handling both vertical and horizontal drilling tasks simultaneously. The top drilling unit contains (Vertical 12 + Horizontal 8) × 2 groups, while the bottom includes 9 vertical bits, ensuring versatile and efficient processing for various panel sizes. With a milling spindle of 3.5 kW * 2 (one top and one bottom), these machines also perform six-sided machining, including drilling, grooving, and milling. This configuration enables clients to handle complex production tasks while maintaining accuracy and speed.

Advantages of Our CNC Boring and Drilling Machines

We provide our agents with comprehensive support, from machine selection to after-sales service. Our cnc boring machine and cnc drilling machine are designed with multiple patented appearance features, reflecting both functionality and modern aesthetics. In addition to high-quality manufacturing, we offer free consultation for complete factory layouts, helping clients optimize production capacity. For overseas partners, we create professional after-sales support groups to solve any issues promptly and can send engineers to assist with on-site installation, training, and debugging. Common questions such as delivery time, local agency availability, and after-sales support are addressed through these services. Typically, standard models have a delivery time of around 30 days, while customized machines or complete production lines depend on project specifics. We are actively seeking agents globally, and interested parties can contact our regional sales teams for details.

Conclusion

At HUAHUA CNC, we take pride in combining technological innovation, high-quality standards, and dedicated service to provide machines like the cnc drilling machine and cnc boring machine that are reliable for panel furniture production. Our engineering team, led by German experts, ensures every unit meets precise standards, while our specialized frame manufacturing base guarantees consistent quality. By offering flexible customization according to market requirements, as well as optimized production solutions and professional after-sales support, we foster strong partnerships with agents and clients worldwide. For those seeking dependable woodworking machinery for commercial-scale production, HUAHUA CNC machines represent a robust solution tailored for efficiency, precision, and sustainability.