Precision and efficiency are key to successful panel furniture manufacturing. At HUAHUA CNC, we provide professional-grade solutions designed for industrial woodworking operations. Our pvc edge banding machine offers manufacturers the ability to process various panels with consistent quality, while the edge banding machiner ensures accurate trimming, gluing, and finishing. We have leveraged years of CNC experience to create equipment that helps partners maximize production efficiency while maintaining high standards of craftsmanship.

Comparing ABS and PVC Edge Banding

Understanding the differences between ABS and PVC is crucial for choosing the right edge banding material. ABS is valued for its flexibility and impact resistance, making it suitable for applications where panels may experience higher stress. PVC, however, provides a broader range of colors, smooth application, and cost-effectiveness for large-scale manufacturing. Using a pvc edge banding machine, manufacturers can efficiently apply PVC edges, achieving panels that meet both aesthetic and functional standards. The edge banding machiner supports precise application, reducing material waste and enhancing the overall appearance of finished products.

Innovative Features and Production Optimization

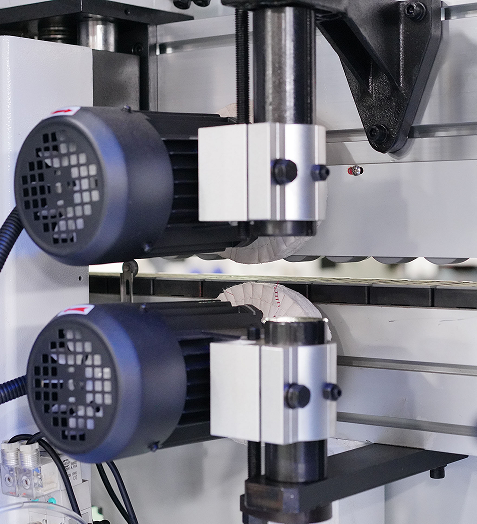

Our pvc edge banding machine incorporates a Buffing Unit with two rotating cloth wheels, ensuring panels are polished evenly and edges appear smooth and visually appealing. This system also helps maintain uniform wear on the polishing wheels, extending service life. At HUAHUA CNC, we provide free consultation for complete production line planning, assisting clients in designing optimized workflows to achieve higher productivity. Our machines are customizable to accommodate different board sizes and furniture types across international markets, helping agents adapt solutions for local production requirements.

Supporting Global Partners and Agents

We prioritize reliable after-sales support to build long-term partnerships. For overseas agents, we provide detailed installation videos, establish professional service groups for real-time troubleshooting, and can dispatch engineers to client sites for on-site guidance and training. Standard models typically have a delivery time of about 30 days, while customized machines or full production lines are scheduled according to project needs. Many markets already have HUAHUA CNC representatives, but we are actively seeking new agents worldwide, offering cooperative pricing, promotional support, and comprehensive technical assistance to help partners succeed in their local markets.

Conclusion

Selecting the proper edge banding material and machinery is essential for professional panel furniture production. Our HUAHUA CNC pvc edge banding machine and edge banding machiner combine innovative technology, precise finishing, and robust support to meet industrial requirements. By partnering with us, agents and manufacturers gain access to high-quality equipment, tailored production solutions, and professional guidance, ensuring consistent, efficient, and visually appealing results in every project.