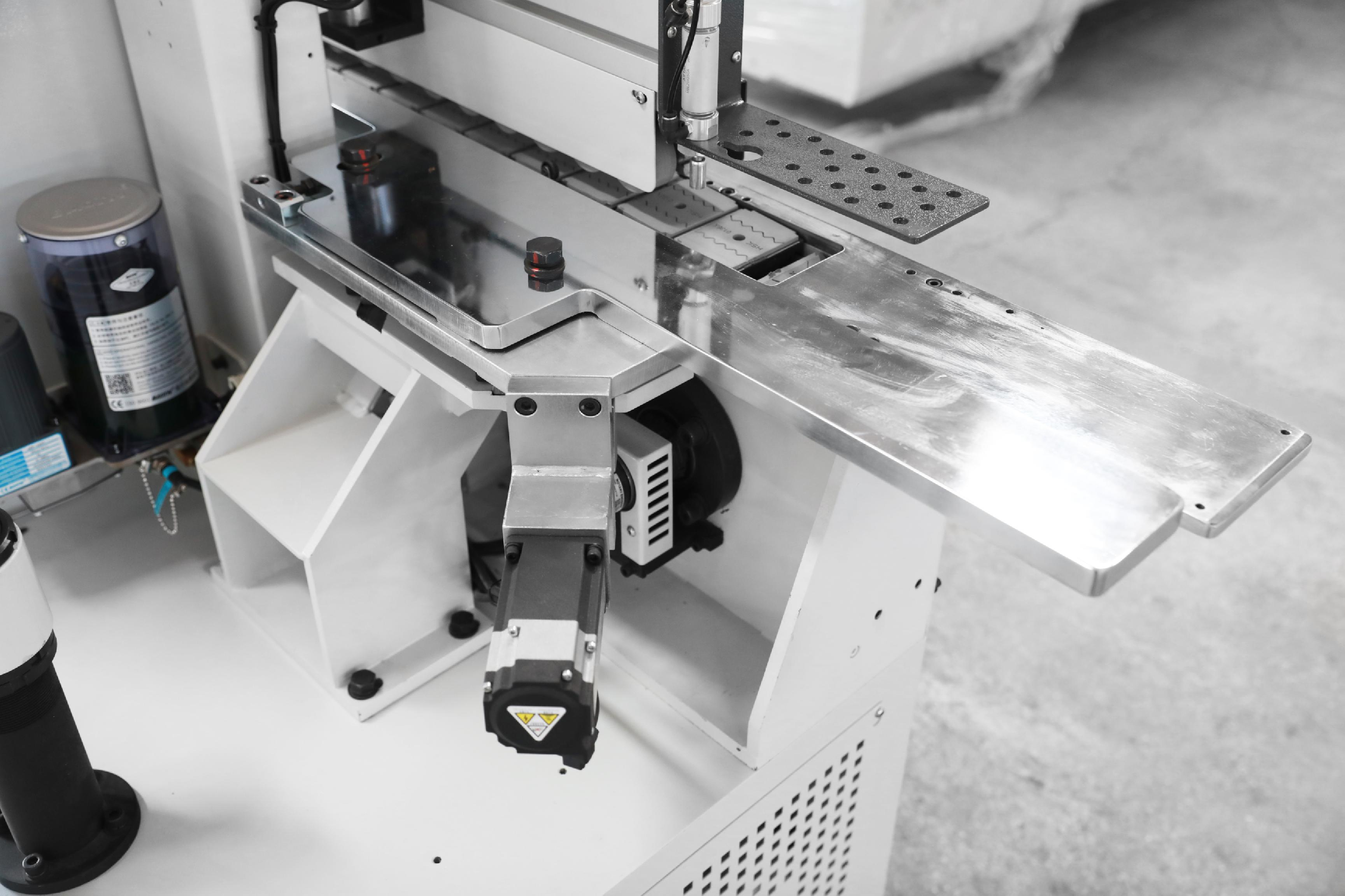

Edge finishing is a crucial step in panel furniture production, and at HUAHUA CNC, we fully understand the importance of precision, consistency, and efficiency in this process. Our automatic edge banding machine has been developed to deliver reliable, high-quality results for every project. By integrating advanced technology, including the Servo Positioning Plate, we can ensure that each panel is positioned accurately during the edge banding process, which reduces errors, improves material utilization, and enhances overall productivity. Over the years, we have worked closely with furniture manufacturers around the globe, focusing on helping our partners optimize their production lines and achieve higher efficiency in competitive markets.

Understanding Edge Banding on Wood

Edge banding wood involves applying a protective and decorative strip along the exposed edges of panels to enhance both durability and appearance. This process is essential for maintaining a professional finish and preventing damage during handling and transport. At HUAHUA CNC, we have designed our automatic edge banding machine to provide precise, consistent application across different panel types and materials. The use of automated systems ensures uniform results while reducing manual labor and minimizing material waste. We recognize that companies aiming to maintain high standards in panel furniture production need equipment that combines reliability, speed, and user-friendly operation, which is exactly what our machines deliver.

Tailored Solutions and Comprehensive Support

We understand that every factory and market has specific requirements, so we offer free consultation services to help clients design optimized layouts and production workflows. Our team assists partners in selecting suitable machines, planning factory arrangements, and implementing effective processes. For overseas customers, we provide detailed installation videos and establish dedicated service group chats to respond promptly to any inquiries or issues. We can also arrange engineers to visit client sites for installation guidance, machine tuning, and product training. Partners frequently ask about delivery times, after-sales support, and local agent availability. We ensure responsive service through professional channels, with standard machines typically delivered within thirty days. Customized models or complete production lines are tailored according to specific requirements. Some countries already have agents, and we are actively seeking new partners globally to establish long-term, mutually beneficial cooperation.

Commitment to Quality and Innovation

At HUAHUA CNC, our dedication to product quality, technological innovation, and partner success distinguishes our approach. Our automatic edge banding machine ensures accurate application on edge banding wood, while our patented designs, robust construction, and precise engineering provide reliable, long-lasting performance. We are proud of our passionate research and development team, led by German engineers who bring advanced European technologies and standards to our equipment. Our facilities include dedicated production bases for machine frames, ensuring stability and high-quality output. With domestic 3C certification and European CE certification, we guarantee that our machines meet rigorous quality and safety standards. Through flexible customization, comprehensive consultation, and proactive support, we help our B2B partners maintain efficient, high-quality production and successfully expand their business in local and international markets.