In the evolving field of woodworking machinery, we at HUAHUA CNC focus on developing intelligent and efficient cutting solutions that meet the demands of modern furniture and panel production. Among our key innovations, the wood band saw plays a crucial role in achieving precise, stable, and high-speed cutting performance for large-scale manufacturing. Understanding what a wood band saw is used for provides valuable insight into how this essential machine supports industrial production efficiency.

The Core Function of a Wood Band Saw

A wood band saw is designed for precise cutting of various wood materials, ensuring smooth edges and consistent dimensions across production batches. In industrial settings, it helps manufacturers process large panels efficiently, reducing waste while maintaining accuracy. Unlike small workshop tools, our saws are engineered for continuous operation, combining durability with intelligent control. At HUAHUA CNC, we integrate powerful motors and automated positioning systems that make each sawing process both accurate and effortless, helping our clients improve productivity and quality at the same time.

Product Advantages and Technical Highlights

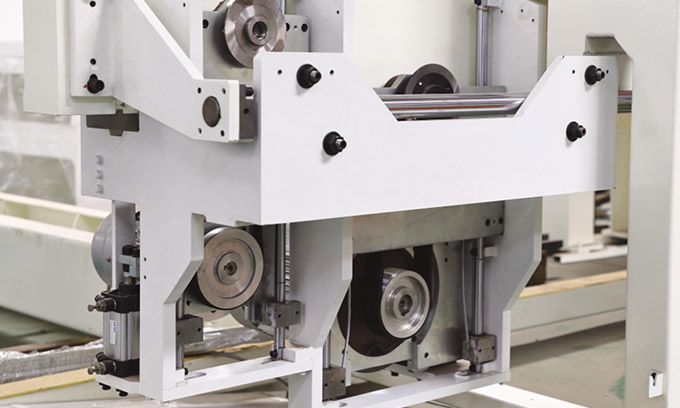

Our CNC Panel Saw line demonstrates how advanced sawing systems can transform furniture production. Each unit features a saw carriage with independently lifting main and scoring saws, and an automatic sawing stroke adjustment that adapts to different cutting thicknesses and widths. The 18.5 kW main saw motor ensures strong cutting performance, while fast blade replacement reduces operator fatigue and production downtime.

In addition, we provide free consultation services for complete factory layout design, helping customers build the most optimized and efficient production lines. To meet global market needs, we also accept customization based on local board dimensions and furniture types. This flexibility enables our partners to deliver high-quality products tailored to their regional standards.

Global Cooperation and After-Sales Support

We aim to build strong partnerships with distributors who have their own sales and service networks. To support these partners, HUAHUA CNC offers competitive agency pricing and a comprehensive support system, including 24-hour after-sales service, professional group chats for technical assistance, and onsite engineer training when needed. Our machines are certified with CE and 3C standards, ensuring safety and reliability for international clients.

Conclusion

The wood band saw remains a key component in professional wood processing, essential for precision, speed, and production scalability. At HUAHUA CNC, we are committed to advancing sawing technology and providing integrated solutions that empower our partners to grow their businesses with confidence. Through innovation, quality manufacturing, and dedicated service, we continue to strengthen our presence in the global woodworking machinery industry.