What are the edging tapes made from? There are different materials, and we’ll focus on a few here.

PVC

PVC is the most popular material for edge banding in the case of good tops. Pros: It’s inexpensive, durable, and boasts a long life. It doesn’t require any finishing process. It’s also easy, albeit tedious, to repair. Cons: You can’t recycle it. It doesn’t biodegrade. Once it’s blemished, you can’t refinish it. (NB: ABS—Acrylonitrile Butadiene Styrene—is an eco-friendly alternative to PVC because it’s both recyclable and safe to incinerate.)

Regarding PVC, we recommend 3mm edging in general because it goes on cleaner, quicker, and with better adhesion. Another advantage is that you get a graceful radius and a nice soft-looking finish. We generally avoid .5mm edging because the corners are too sharp.

Solid Wood

Solid Wood is still a favourite for case-good tops in many woodworking camps. It’s durable, recyclable, easy to fix and refinish, strong, stiff, and economical.

Benefits: it’s more resistant to chipping than veneer edge tape. Solid wood glues are more reliable and less prone to peeling than veneer and PVC. It provides additional dimensional support to plywood and MDF. Climate-neutral manufacturing. Cons: Difficult to use for curves.

We offer solid wood edge banding for tops in a range of thicknesses. And you can apply it internally or externally.

Regarding solid wood, we recommend 9.5mm for good tops.

As we explain below, at HUAHUA, we believe the best way to apply wood edge banding is “internally” with an HPL top. Why? Because, in our experience, it’s incredibly durable and never requires additional service.

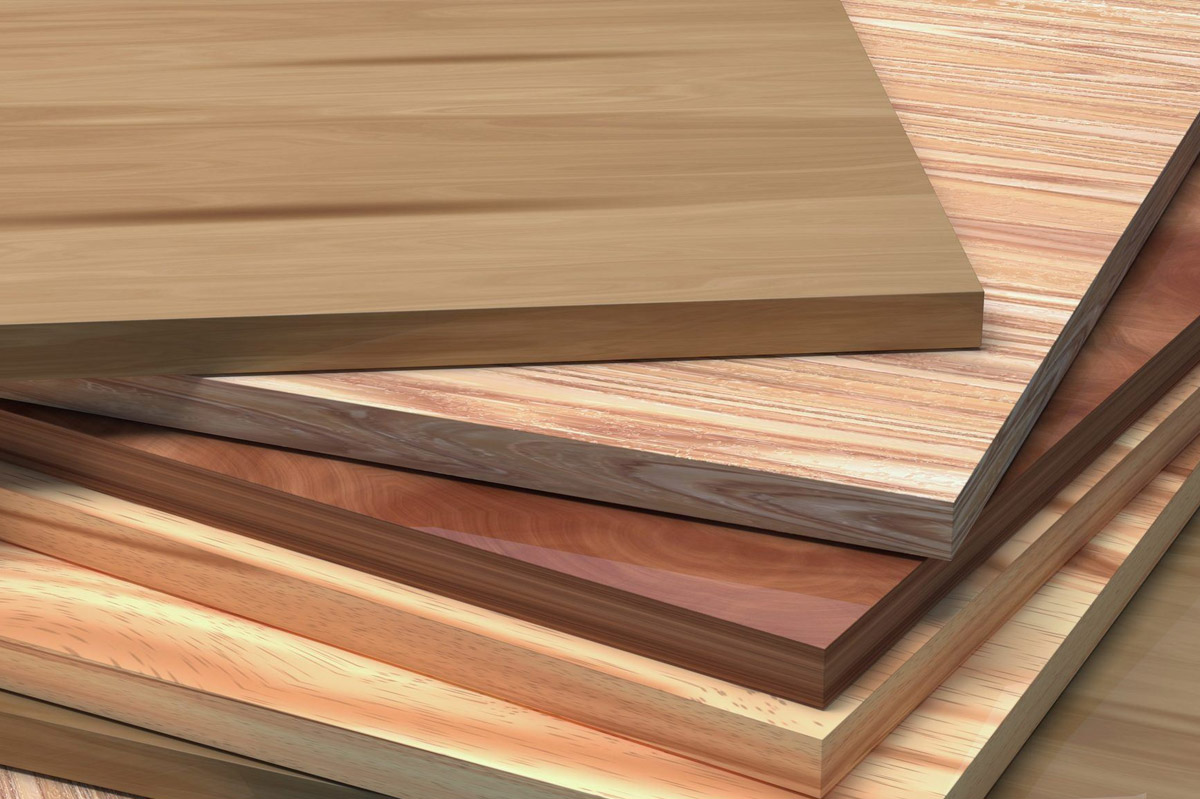

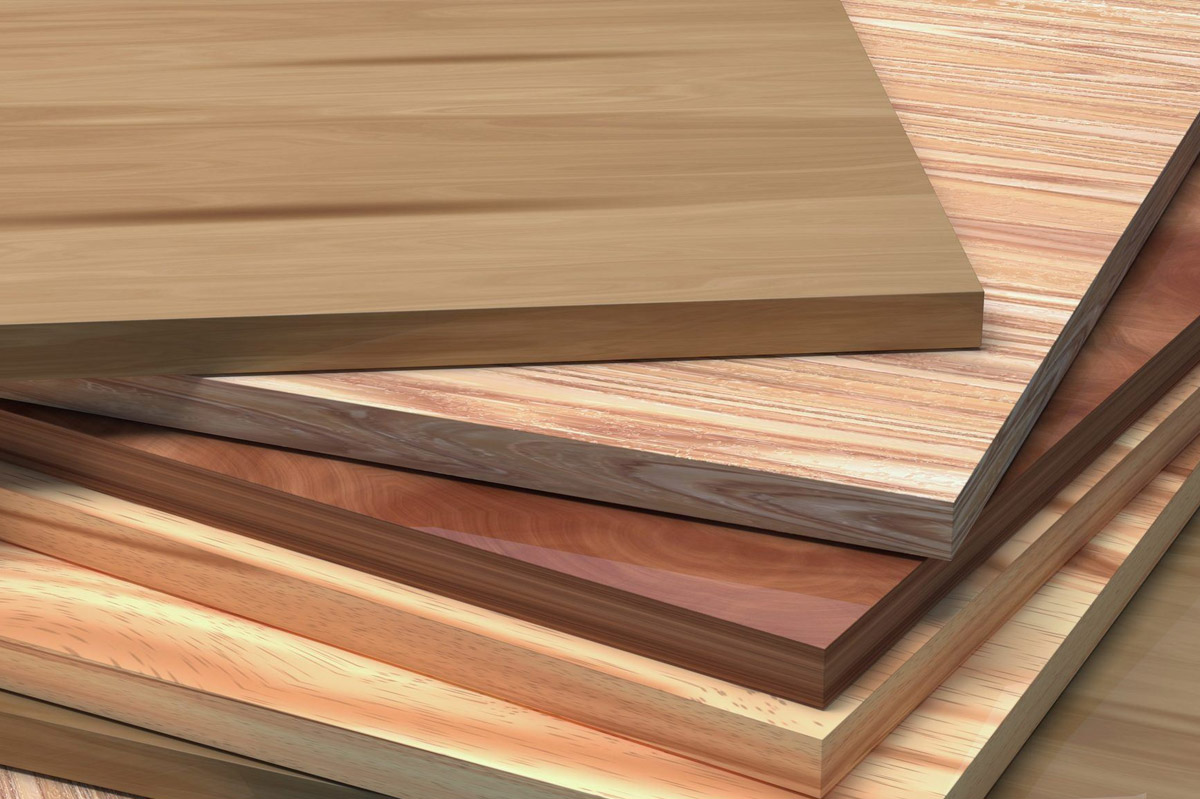

Wood Veneer

Wood Veneer is the most common edge banding material for plywood cabinet sides, drawer fronts, and MDF wardrobe doors. It’s made from thin slices of wood—typically oak, maple, ash, walnut, birch, and mahogany—that are joined together in a roll using finger jointing.

It usually features a heat-sensitive glue backing. And it comes in a range of thicknesses, so it’s essential to use the right one depending on the application.

Pros: It’s attractive, durable, and strong. It provides a clean solid-wood look, and it’s pre-sanded to absorb stains and finishes and seamlessly match your wood. Cons: It’s not heat resistant. Avoid putting it near a heater. It doesn’t do well in high-use environments.

How is edge banding applied?

According to RA Learning Center, at least four methods of applying edge banding exist. There are many things to say about each of these, but for now, here’s a simple list of application methods and mediums.

Hot-melt glue

Hot air/laser

Iron-on

Laser edging